Table of Contents

- What Is Supplier Master Data?

- Common Data Challenges in Modern Supply Chains

- The Importance of Master Data Management in the Supply Chain

- Key Components and Data Domains of Supplier Master Data Management

- How Supply Chain Master Data Management Operates in Practice

- How to Implement MDM for Your Supply Chain Management

- Supplier MDM Implementation Best Practices

- Overcoming Common Challenges of Master Data Management in Supply Chain

- Future Trends in Supply Chain Master Data Management

- Real-World Examples of MDM in Supply Chain

- Create Trusted Supply Chain Master Data with Profisee

- Frequently Asked Questions About Supply Chain Master Data Management

Key Takeaways

Supplier master data domains include supplier data that doesn’t often change, including location, contacts, payment terms, products and contracts.

Supplier master data management helps companies overcome data challenges due to incomplete, incorrect or inconsistent data.

Supplier master data management is a continual business practice that can optimize data ingestion, cleansing, governance and analysis. These processes lead to positive business outcomes across the supply chain.

The Profisee supply chain MDM platform uses automation and AI-powered data matching to build trusted data that drives strategic supply chain improvement initiatives.

Supply chains produce complex connections between businesses with widely different processes, data formats and regulatory requirements. They require businesses to share vital data including product naming conventions and specifications, regulatory requirements, contractual agreements, pricing, locations and logistical needs. Supply chain master data management seeks to make these data domains usable, consistent and reliable.

Accelerate Microsoft Fabric Success

What Is Supplier Master Data?

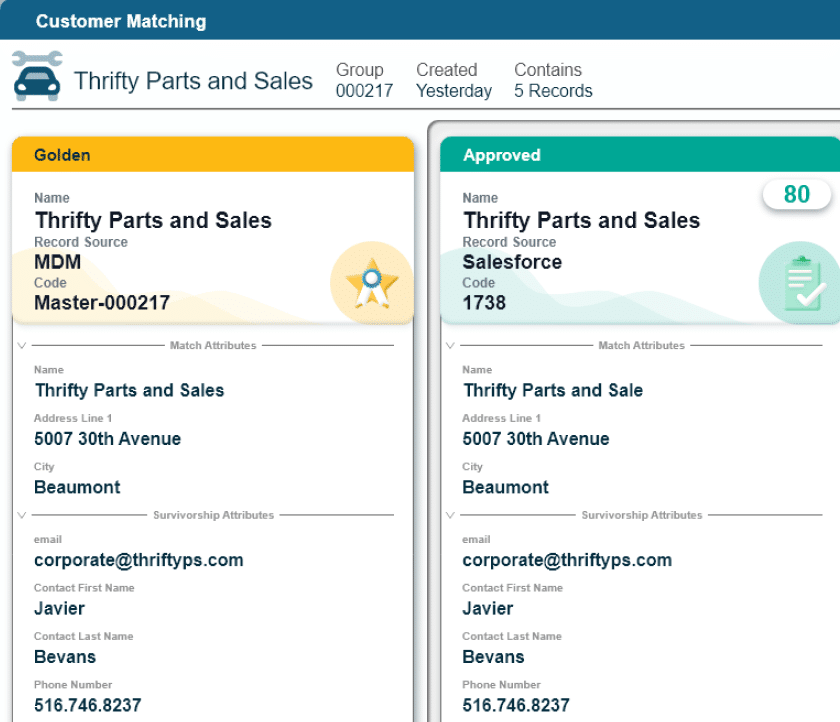

Supplier master data is the foundational data that doesn’t change often and is used to make critical business decisions and increase operational efficiency within a manufacturing supply chain. Supplier data can be considered master data or “golden record” data when it has been cleansed, de-duplicated, enhanced and stored according to agreed-upon formats and standards. These processes make supplier master data usable across software systems throughout the business.

A manufacturing business that standardizes their supplier master data significantly increases their potential for operational efficiencies and cost savings.

Common Data Challenges in Modern Supply Chains

Data from any industry is prone to error, and that tendency increases as the number of software types, locations, products, and customers that make up the supply chain and business grows. A 2024 survey by the Manufacturing Leadership Council reported that over 70 percent of manufacturers still enter data manually. That’s a lot of opportunities for small errors. What initially causes a bit of confusion can grow into difficulties transferring, communicating and interpreting data across entities

Add to these challenges the common data problems that integrating new software across business silos, and business data can quickly become unmanageable. When a manufacturing company employs a supplier master data management platform, it organizes and standardizes crucial business data domains that support increased operational efficiency, reduced waste, and increased internal oversight.

Modern supply chain data can quickly become messy due to the number of people who enter, modify, or otherwise touch records along the product lifecycle. Each of those touches carry the risk of human error, which can cause duplicate or near-duplicate entries that can slow down production or operations at every stage in the supply chain. Major challenges include:

- Multiple data touchpoints

- Duplicate or inconsistent entries

- Data silos

- Limited partner transparency

- Poor visibility beyond Tier 1

- Wider business impacts

Data silos created by departmental, software, location or other organizational divisions can further complicate data formats, as usable versions of data may not transfer easily across these borders. A lack of transparency between partners due to long-standing internal processes or software that doesn’t share data easily can further disrupt information transfer across parts of the supply chain. According to KPMG’s Supply Chain Trends 2024, less than half (43%) of the organizations surveyed have visibility into data beyond their Tier 1 partners. That leaves a lot of room for optimizations.

These challenges have far-reaching effects, including failure to meet regulatory and cybersecurity compliance standards, slowed processes, inaccurate record-keeping, and more. Supply chain master data management alone won’t solve all of these challenges, but it can reduce their impacts on business outcomes.

The Importance of Master Data Management in the Supply Chain

Master data management in supply chains breaks down silos, organizes data, builds trust among partners and makes the overall supply chain more efficient in several ways.

Faster Supplier Onboarding

When governance is in place, data collection from new suppliers goes quickly, as all pertinent information can be gathered at once. Upon building that single golden record, the supplier information management allows sharing with other systems across sales, operations, logistics and finance.

Fewer Procurement Errors

Supplier master data records make pricing, location and product availability searchable and accessible, allowing for teams to make accurate purchasing decisions that increase margins. This is especially helpful for industries where products can have nuanced differences that make a big impact. The organization can save time and headaches by getting orders right the first time.

Better Inventory Visibility

Inventory visibility — or lack thereof — affects the entire supply chain data management from retail, warehousing, shipping and logistics as well as supply and procurement. Consistency in product naming and parts or ingredients data makes inventory numbers less confusing and more visible to the entire organization. This transparency leads to better decision-making for purchasing, production levels, and stocking.

Improved Analytics and Reporting

Downstream effects of manufacturing master data management include improved analytics and reporting because everyone in the organization can trust that the data is correct and complete. Reliable data can be segmented, analyzed and investigated to show root problems that can be trusted for decision-making, instead of being caveated within reports as incomplete or containing unknown variables.

Improved analytics build a resilient supply chain with MDM.

Stronger Compliance and Risk Mitigation

Compliance and risk mitigation rely on consistently followed processes that allow for tracking and audit trails. Creating master data for the supply chain with a data workflow increases the reliability of data while making all data visible to auditors and stakeholders. This has the added benefit of surfacing risks early so the organization can respond quickly.

Key Components and Data Domains of Supplier Master Data Management

While each supply chain and organization has unique processes and data needs, several data domains or types of data appear consistently among supplier master data management projects.

A successful master data management project will begin by identifying domains that are important to the business as a whole and choosing the domain with the greatest impact to start with. Consider starting with these domains:

Supplier Data

Unifying supplier data will speed sourcing during the run of normal business and those times when the organization needs to quickly pivot to new suppliers or those with inventory. Supplier master data management can also illuminate which transport companies have access to suppliers and reduce logistics and storage prices. Consistent supplier contract terms and product lists help procurement, finance and legal teams to make better decisions faster.

Item or Product Data

You know well that items and products are more than their final form — they’re the component parts and supplies that need to be tracked for regulatory compliance and item quality. Supply chain item master data management ensures adherence to product specs, quality, sustainability efforts, and will add efficiency to sourcing and inventory efforts as well.

Location Data

Having the correct location data, including addresses, phone numbers and hours can make a difference in the timeliness and accuracy of logistics. Whether a delivery or pick-up happens on time can have downstream effects on inventory, contracts and even quality due to storage deficiencies. Companies should also manage manufacturing data, like locations, to increase efficiency when manufacturers choose suppliers and logistics carriers.

Contract Data

Including contracts in a single repository allows for quick reuse and reference that speeds sales processes and compliance checks from legal departments. Having a single stored version of the most recent contract keeps all parties aware of details and changes as they occur to enforce quality and logistical agreements.

Pricing Data

Pricing can be overlooked within master data management in supply chain operations as it’s largely considered the purview of the sales department. But having consistent sales numbers that achieve necessary margins keep all teams from over or under-promising on products. Additionally, having documented pricing across all suppliers enables faster decision-making when substitutions are needed due to supply chain disruptions.

How Supply Chain Master Data Management Operates in Practice

Supply chain master data management is the sum of several processes from data collection through distributing that data back to systems. An MDM solution for manufacturing ingests data, cleanses it and pushes usable data out to business systems. Best practices suggest working on a single domain. For the purposes of illustration, our example is for supplier locations. Here’s how supply chain master data management operates in practice:

- Data ingestion: Supplier location data is pulled from business systems into a centralized database via extract transform and load (ETL), CSV documents or API connections.

- Data matching and deduplication: The process of sorting begins. All addresses are combined into a single list, and any duplicates are flagged, reviewed and reduced to a single entry. This process happens for each of the items in the supplier location domain.

- Validation and enrichment: Each of the address lines runs through validation. For example, you might plug each item into a third-party map and compare results with the data list. Data analysts will then correct any items that need it and complete partial items.

- Data governance workflows: The team devises and enacts processes that enable business users to input correct data or automations that transform data from systems to usable, reliable data.

- Synchronization with systems: Usable, golden record data is transferred from the MDM back to the source software. Active governance workflows ensure new data meets the threshold of reliability.

Consider supply chain MDM as a continual process and everyday practice rather than a one-off project, as business users must adjust to ways of working that support the collection and maintenance of reliable data within all systems.

How to Implement MDM for Your Supply Chain Management

Whether you’re launching your first domain initiative or looking to rework a current project, these steps will help you clarify your needs, build processes and implement the project in a repeatable, scalable way.

1. Identify Key Data Domains to Manage

Start by looking at the ways your teams use data, prioritizing domains like supplier, item, location and bill of materials. Ask the team what domains they use the most, and where they find they have to use workarounds or manual entry within their processes. When you choose the key data domains to manage, focus on where poor data creates the most friction.

2. Assess Data Quality and Sources

Using the domains you chose in step 1 as a limiting factor and guide, perform a data quality audit across ERP, procurement and inventory systems. Also consider other business data tools like CRM, contracts, and financials that use the domains you chose. Within the data from those sources, identify duplicates, gaps, and inconsistencies to fix or fill.

3. Define Data Governance and Ownership Models

Establish who owns what data and which processes. For manufacturing organizations, ownership may lie outside of the data team with a business user whose work brings them into consistent, direct contact with the data.

Consider the internal roles of data stewards, business users and IT, and assign data ownership roles that make sense according to your business processes. Data owners can then contribute to documentation, like approval workflows and quality standards that meet their business needs and support the supply chain.

4. Select the Right Supply Chain Master Data Management Platform

Not all supply chain master data management platforms can support the needs of manufacturing organizations. Look for systems that support multi-domain MDM, as these platforms will scale along with your master data initiative.

You also need a solution that integrates with key business software data sources you already use, including ERP, manufacturing execution system (MES) and product information management (PIM) software. Finally, choose an adaptive MDM platform that allows your team to set up rule-based management that automates new data management.

Read more: PIM vs. MDM: Which is right for your organization?

5. Configure Data Matching, Survivorship and Validation Rules

While we’d love to provide you with rules and templates ready-made for governance, you’ll need to tailor data matching logic and data survivorship rules to reflect your manufacturing and sourcing realities.

Special cases like vendor hierarchies and item versions can make a big difference in how usable the output data is for business users. Confer with them on outliers and the manual processes they use in-house to match your rules with everyday work, and consider automating master data management to speed the data cleansing process.

6. Launch in Phases with Clear KPIs

While it’s tempting to try to complete the entire project and roll it out in one go, master data management needs an iterative, test-based implementation. Begin your rollout by domain or plant, choosing your launch based on the biggest potential impact vs. the relative cost, and set your KPIs beforehand based on business need or industry standards.

Consider KPIs that measure impact on onboarding time, error rates and inventory visibility. Use early wins to inform future planning before expanding to more domains or locations.

Supplier MDM Implementation Best Practices

You can identify a project that will result in a successful supplier MDM rollout because it shows evidence of a couple of key best practices:

- Secure stakeholder buy-in and effective change management: A successful supply chain data management program has widespread support for the changes, a defined communication strategy and a comprehensive training plan. These features prove the strategic importance of the initiative.

- Clearly defined data ownership, governance bodies and stewardship roles: The successful data strategy will communicate with all parts of the organization, but decision-makers can work quickly when needed.

- Emphasis on data standardization and continuous improvement: Yes, you want all the outcomes. A successful MDM strategy plans for today’s outcomes and tomorrow’s process improvements. Thinking of MDM as an ongoing, iterative strategy pays off because further changes can be iterative rather than sweeping.

- Leveraging automation and AI/ML to enhance matching and classification: Automating manual processes wherever possible will increase the speed and success of the program.

These best practices add up to an MDM project that gets integrated into the daily workflows of business users and builds an overall culture of data improvement throughout the organization.

Overcoming Common Challenges of Master Data Management in Supply Chain

Common challenges within supply chain MDM can be attributed to two main reasons:

- People don’t like change.

- Complications result in resistance.

When people hear of a new project, they may initially react with resistance because they think that the initiative will make their lives and work more complicated. Challenges for MDM projects include:

- Normal human resistance to changing daily workflows.

- The need to keep up with governance and regulations across global markets.

- Getting existing software stacks to work together, which might mean changing tech for some groups.

Consistent, clear and value-based communication goes a long way to breaking through employee resistance. Two ongoing priorities to keep in mind are:

- Overcome data silos and meet regulatory standards, as these priorities improve communication and cooperation among teams while improving outcomes for customers.

- Highlight the usefulness of new data workflows to reduce manual work and increase speed speaks to the needs of the business users.

Future Trends in Supply Chain Master Data Management

As technology advances, its applications within supply chains promise to speed production with increased revenue, greater traceability, and fewer costly mistakes. A solid supply chain MDM strategy enables these advancements.

Agentic AI for automated problem-solving

Some see agentic AI, or the use of custom AI agents to complete autonomous tasks between systems, as the next logical step for GenAI. AI agents could work from existing supplier master data to provide logistics solutions for daily work and during disruptions, identify and order based on inventory needs and more. A strong master data foundation is needed to build agents that work quickly and accurately.

AI data matching and enrichment

Companies use AI within MDM platforms to perform complex and time-consuming tasks like data matching and enrichment with limited need for oversight. These tools can match data like misspelled addresses or phone number errors that would otherwise need human eyes to correct. In addition, location data can be verified by internal records and third-party applications and updated if incomplete.

Supplier Risk and ESG data

Supply chain organizations must build supplier risk into their outlooks, considering the potential cost of delays or dropped contracts and the necessary supply changes that come along with those problems. Environmental, social, and governance (ESG) metrics tie companies to their suppliers in potentially risky ways. Improvement in data controls and management can make those risks visible and allow the company to plan or pivot when needed.

Cloud-Native, Scalable MDM

The manufacturing industry is moving to cloud-native MDM solutions that allow for scalable growth beyond the confines of on-premise systems. These tools can quickly connect to existing software, don’t require manual upgrades, and don’t require the purchase of ever-expanding storage systems. A cloud-native MDM platform fits the growing complexity and data needs of the modern supply chain

Real-World Examples of MDM in Supply Chain

- Mastering customer data for industrial automation: Profisee helped a manufacturing company achieve real-time integration, a centralization and consolidation of data, and automated processes within a Microsoft ecosystem.

- Rheem adapts to a changing market with supplier data to identify distributors across major business lines through Profisee’s fuzzy matching capabilities.

- Apogee optimized procurement processes and consolidated eight individual data systems through strategic implementation of Profisee MDM.

Create Trusted Supply Chain Master Data with Profisee

Supply chains aren’t getting less complicated, but you can transform the data your business runs on by creating reliable supply chain records. Profisee’s supply chain master data management platform helps your team build a consolidated, trusted view of data from all of its systems. You can then use your reliable data to build a more resilient and optimized supply chain.

Request a demo to see how Profisee helps companies manage supply chain master data at scale.

Frequently Asked Questions About Supply Chain Master Data Management

Do I need a separate supply chain master data management software if I already use an ERP?

Yes, you need a supply chain master data management software. Supply chain MDM improves the data that you use within your ERP by cleansing, de-duplicating and enriching the data before making it available for use by the ERP and other systems.

What types of systems should my supply chain master data management platform integrate with?

Your supply chain MDM platform should integrate with any software systems that ingest data from customers and partners and any business systems that then use the data.

In particular look to integrate:

- Information systems including PIM, MES, ERP

- Financial software like bookkeeping, invoicing, or accounting

- CRM and sales software like contract management

- Marketing automation and marketing data tools

MDM platforms will help you make the data these systems create and use available to one another and the wider organizations.

What's the difference between supply chain master data and product information management (PIM)?

| Supply Chain Master Data | Product Information Management | |

|---|---|---|

| Incorporates product data | Yes | Yes |

| Incorporates data domains from all departments | Yes | No |

| Primary departments served | All | Marketing, Sales |

| Owner | Centralized, Data/IT | Marketing, Sales |

Will poor supplier master data affect procurement?

Yes. Optimized supplier master data makes it easier to identify suppliers, locations, pricing, and contracts for each of your suppliers. By having a consolidated view of these records, your team can make faster decisions when needed, analyze operational efficiency to find your next best solutions and reduce risk. Poor supplier master data works in the inverse, slowing decision-making and causing confusion when swift action is needed.

Tamara Scott

Tamara Scott is a writer, editor and content strategist with over a decade of experience located in Nashville, TN. Tamara holds a Master's in English from Belmont University, formerly served as Director of Content for TechRepublic, and her work has appeared in ServerWatch and EPI-USE.com, among others. When she's not crafting SEO-informed and conversion-ready content for SaaS and IT service companies, she's probably at home on her pottery wheel. Connect with her on LinkedIn.