Since the onset of the COVID-19 pandemic, increased manufacturing disruptions have unfortunately paved a slow road to recovery for supply chains worldwide.

As we close out 2022, it has become more apparent that global manufacturers need to build more resilient supply chains to respond to these disruptions. Whether they need to onshore production due to regulatory pressures or are scaling production of a new product in response to changing customer demand, bad data can’t stand in their way.

It’s readily apparent how data silos across systems, departments and regions can hinder innovation and a company’s ability to respond to supply chain challenges. For example, if a global manufacturer manages multiple ERP instances as a result of acquisitions, it may be difficult (or impossible) to quickly identify their suppliers, much less identify where they can renegotiate terms or pricing.

Combine that with other trends like manufacturers increasingly marketing directly to consumers or entering completely different markets, and it’s clear how a lack of trusted data can only further compound production issues.

Global Trends Disrupting Supply Chains

In recent years, there have been several new trends disrupting global supply chains.

A sluggish global economy and its many changes have altered the way we work and conduct business. For example, in April 2019, online shopping overtook brick-and-mortar sales for the first time, causing many companies to completely reimagine the way they did business.

All under the larger banner of “supply chain disruptions,” there are several external factors that factor into the current, challenging state for global manufacturers.

Unfortunately, many of these underlying causes cannot be directly addressed by improved supply chain management or procurement strategies.

These include supply chain disruptions caused by:

- Global transportation limitations caused by global conflicts in Europe

- Pressures to onshore production while addressing trade deficits with other nations, including the United States’ commitment to subsidize $52 billion of microchip production to reduce reliance on imports from other counties

- Increased regulatory oversight of environmental, social and governance (ESG) due diligence and reporting directives

However, that is not to say there aren’t manageable factors with real solutions. Supply chain managers cannot control the world, but they can control how they respond to the challenges posed by supply chain disruptions.

With immediate access to high-quality, trusted data manufacturers can more quickly identify and rank their suppliers, market directly to their most profitable customers and quickly analyze data across multiple systems.

Responding to Supply Chain Disruptions with Master Data Management

Manufacturing leaders cannot fully sustain their operations without a strong foundation of enterprise data. Manufacturers need complete, accurate and consistent data about their customers, production, locations and products to answer critical questions like:

- Who are my most valuable customers?

- Where may I have unfavorable supplier terms?

- Do my raw materials overlap across subsidiaries or regions?

It is absolutely necessary to have and maintain a single source of trustworthy enterprise data, regardless of which department “owns” the data or the system of entry. And the quickest, most scalable way to operationalize this is a fully featured, multidomain master data management (MDM) platform.

To optimize their supply chain operations, manufacturers need to proactively address both upstream challenges like sourcing, extracting and procuring raw materials, as well as downstream efforts related to physical distribution, warehousing and transportation. Those are a lot of balls for leadership to juggle!

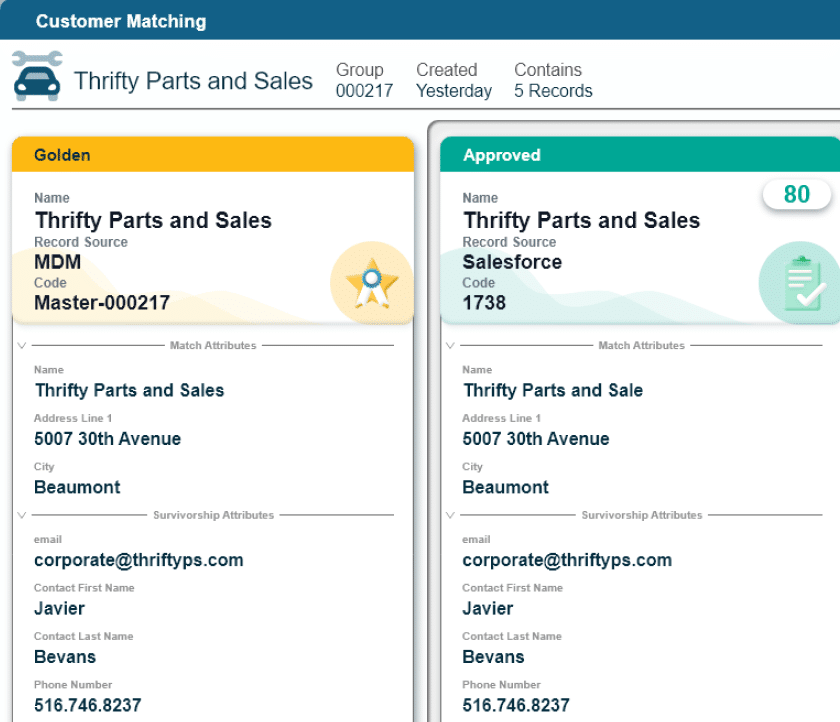

MDM tackles the data-quality issues at the root of today’s supply chain challenges by quickly integrating source systems, merging disparate records and finally breaking down the data silos caused by multiple acquisitions or dozens of ERP instances.

By leveraging trusted golden records of your vendors, customers, products, locations and more, you can finally overcome the data fragmentation problem endemic to so many manufacturing organizations.

Achieving Operational Agility with Master Data Management

Supply chain resilience primarily lies in the ability to quickly respond to operational disruptions and shifts in consumer demand. Manufacturers need to expect the unexpected when it comes to unforeseen factors and pending challenges. Disruptions are unavoidable, but it is how you handle them that determines the resilience of your supply chain.

Agile operations require timely access to important data about your business, particularly enterprise analytics. Master data management can help ensure that the data underlying business reporting is complete, accurate and trusted.

Business intelligence (BI) users can spend their time analyzing the trends and reporting insights to leadership — rather than the endless “clean-up” efforts of tracking data across multiple silos and ensuring it meets reporting requirements.

Agile manufacturing requires organizations to continuously improve based on immediate insights and feedback. And shortening the cycle to high-quality analytics can help manufacturers iterate faster based on accurate information.

Building Resilient Operations with Master Data Management

Responding to current market changes requires an accurate view of both the supply chain and the buyers. MDM provides manufacturers with the clean data necessary for lean chain management. Leaders are provided with a continuous sync from source systems and fast matching and publishing ensure faster feedback from the market used to adjust operations.

When it comes to reducing risks and losses, MDM delivers visibility into all operations across the network while identifying potential risks and allowing enterprises to adapt their manufacturing processes in real time.

According to a 2022 survey from McKinsey & Company, supply chain leaders with high-quality master data were 1.5 times more likely than their peers to report no challenges from the 2021 supply chain impacts. High-quality data were also associated with lower levels of recent supply chain disruptions.

With cleaner and more consistent data, manufacturers were able to develop a complete understanding of the raw materials, suppliers and production elements that comprised their business.

During a time of global uncertainty and constant disruption, those who made the right investments in their enterprise data were able to leverage it when they needed it most.

Despite unexpected global circumstances rapidly changing the marketplace and disrupting supply chains, MDM can still reduce or help prevent several manufacturing issues by maximizing your data quality making it actionable for your business.

You can’t control the world, but you can control your ability to respond to the challenge.

Read the Full Guide on Manufacturing Data Strategy

Building up supply chain resiliency and promptly responding to sudden shifts in the marketplace requires a smarter, more modern approach to manufacturing data management. Read the full guide on Mastering Manufacturing Data below to learn how you can finally overcome the data-quality issues standing in the way of your strategic initiatives.

Forrest Brown

Forrest Brown is the Content Marketing Manager at Profisee and has been writing about B2B tech for eight years, spanning software categories like project management, enterprise resource planning (ERP) and now master data management (MDM). When he's not at work, Forrest enjoys playing music, writing and exploring the Atlanta food scene.