Supplier Master Data Management (MDM) Platform

Get a comprehensive, 360-degree view of your suppliers and optimize supplier relationships for strategic procurement.

Profisee for Supplier Master Data Management

With Profisee for supply chain MDM, create golden supplier records to:

OPTIMIZE PROCUREMENT Profisee lets you integrate supplier and vendor data from all your systems to negotiate better contracts, analyze changes in demand across locations and better evaluate vendor performance.

How Supply Chain Master Data Management Can Streamline Procurement

Better procurement starts with better data.

Negotiate better supply chain contracts with the full picture of your relationship across business lines and subsidiaries

Comply with regulations by understanding the full picture of your supplier’s relationships and hierarchies

Understand which vendors perform well and which ones don’t to negotiate better terms

Improve Vendor Relationships with Supplier Master Data Management

Track Supplier Performance

Easily maintain up-to-date, accurate data about how suppliers and vendors perform across the organization, regardless of source system.

Evaluate Supplier Compliance

Ensure your suppliers are compliant with regulations and company policies around areas such as security, sustainability and their full product lifecycle.

Optimize Supplier Relationships

Assess the value of your suppliers not just in terms of who has the lowest prices, but who provides the greatest overall value to your organization.

The Impact Our Customers Are Making

hours saved correcting data

LEARN HOW CUSTOMERS HAVE OPTIMIZED

THEIR OPERATIONS WITH PROFISEE

Mastering Customer, Location and Supply Chain Data at Scale

Learn how Domino’s used Profisee to link POS products to supply chain inventory item SKUs in its stores’ commissaries to achieve greater operational efficiency.

Consolidating Operations for the Global Brewing Process

Learn how ABInBev used Profisee to simplify recipe management data and consolidate operations across the global, regional and local levels.

Driving Strategic Procurement with Profisee

Learn how Apogee uses Profisee to standardize and harmonize its data across multiple ERP systems to identify matching vendors among business units.

Experience the Power of Profisee Supplier MDM First-Hand

Watch an on-demand demo or schedule a customized demo to see the Profisee platform for yourself and learn how it can help you manage supplier master data.

Supplier MDM Frequently Asked Questions

What is Supplier Master Data Management?

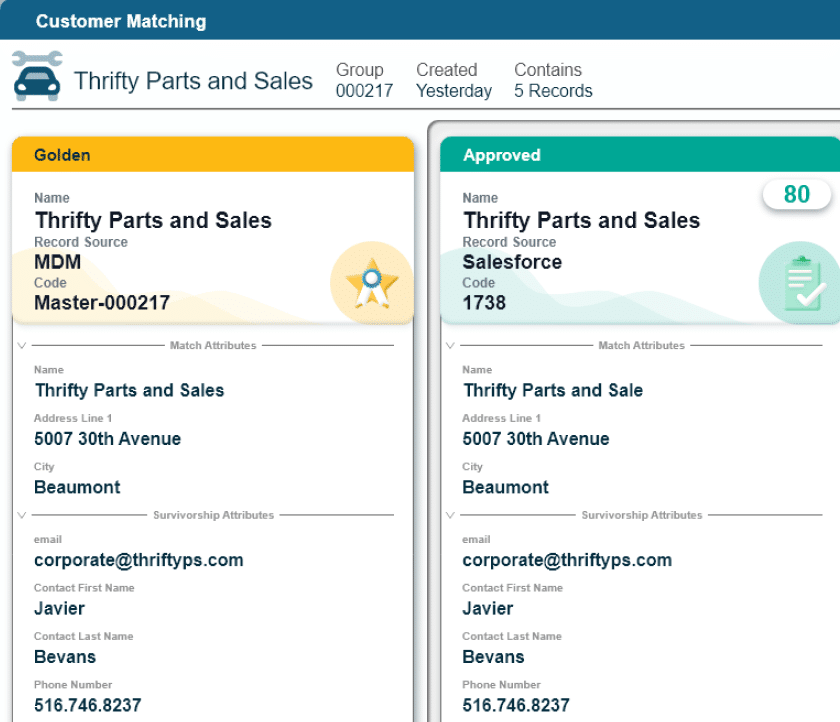

Supplier master data management is the practice of managing the master data generated by your suppliers, including its metadata and reference data. A subset of master data management, supplier master data management refers to the process of:

- Consolidating master data records about suppliers

- Identifying potentially matching records

- Merging similar records while keeping the best, most representative data

- Eliminating duplicate records

- Making the resulting golden supplier records available to all the people and systems that need to access it

Data professionals manage supplier master data using a supplier management platform or a master data management tool. From there, master data can be accessed by different systems like ERP, BI, CRM, data lake or marketing automation.

What Are the Benefits of Supplier Master Data Management?

There are many benefits of supplier master data management, but some of the most notable include:

- Improved supplier relationships

- Enablement of strategic procurement

- Reduced costs

- Increased operational efficiency

- Reduced risk

- Compliance with global regulations like Know Your Supply (KYS), digital product passports and more.

- Better forecasting and planning

Other benefits might include better compliance, shorter onboarding times for new suppliers and the ability to negotiate better contracts with suppliers.

What Are Some Supply Chain Master Data Management Best Practices?

Many supply chain master data management best practices are often consistent with those for MDM in general. But here are a few considerations when deciding how to best implement supplier MDM:

- Identify Master Data Source Systems: Where is data about your suppliers generated? Is it through your ERP systems? A supplier management platform? Somewhere else? One of the first steps you’ll take with supplier MDM is to integrate your supplier data, so it’s important to nail this down early and make a list.

- Consider an MVP Data Governance Strategy: If you haven’t already, you will want to understand how data governance will factor into your MDM strategy. While closely related, data governance and master data management are not the same thing. Data governance is used to create and catalog rules or policies that govern how data is handled to maintain high data quality. Master data management works with data governance to enforce those rules through the process of matching, merging and standardizing data.

- Identify Data Stewards: Data stewards are the people who work hands-on with your supplier data, and they should be intimately familiar with both the data sources it comes from and how it should be corrected according to the company’s data governance policies. The owners of each master data source, the solution architects implementing the MDM solution or business consultants typically identify data stewards during an MDM scoping and implementation.

- Consider the Best Data Model for Your Business: Choose which attributes your master data records should include in addition to their size, data type, allowed values and more. This often requires input from multiple different stakeholders and should be configured with business stakeholders and use cases in mind.

- Review Your MDM Program Regularly: Business leadership changes. Old source systems are retired, and new ones are added. Suppliers come and go. Your MDM program should be flexible and adaptive enough to accommodate the constantly changing nature of a modern organization, so it’s important to check in on your processes and data model at regular intervals to ensure it still serves the company’s business needs.

How Can Supplier Master Data Management Improve Procurement Efficiency?

Supplier master data management (MDM) improves procurement efficiency by centralizing and standardizing supplier master data across systems. This eliminates duplicate records, incomplete profiles and outdated details, creating a single, trusted version of supplier data called golden records.

Working from the golden records lets procurement teams:

- Implement data validation to speed up onboarding with pre-validated records

- Negotiate better terms by adopting supplier 360 to get full visibility into spend and supplier performance

- Reduce errors in purchase orders, invoices and contracts caused by inconsistent data

- Automate approvals and compliance checks that would otherwise require manual review

The result is fewer delays, fewer mistakes and a procurement process that runs smoother and costs less to operate.

What Are the Challenges of Managing Supply Chain Data and How Can You Overcome Them?

Because supply chain data is usually fragmented across ERP systems, spreadsheets, supplier portals and legacy tools, it’s difficult to stay on top of data management. Some common challenges associated with supply chain data include:

Data Silos

Data silos tend to spring up within organizations organically when teams working independently need to limit access to a particular set of data in some way (e.g., ensure only authorized users can view or edit data, ensure a process only gets the data it needs to run) or when a team generates data in isolation (e.g., customer account creation, order creation).

These silos are problematic because they prevent teams from seeing the same information at the same time in addition to causing data quality issues that can lead to confusion and mistakes. One solution to supply chain data silos is to break them down by implementing master data management to integrate, deduplicate and standardize the data so that all teams are working with the same data records.

Poor Data Quality

It’s hard to be a data-driven business when the business can’t trust the quality of the data it has to work with. When data can’t be trusted, analysts can’t forecast trends or spot patterns, marketers can’t confidently speak to your customers’ wants and business processes that rely on solid data to operate grind to a halt.

Not to mention the compliance or reputational damage poor quality data can cause. Without complete, consistent and up-to-date supplier data, submitting incident reports to regulatory bodies is difficult. Inconsistent product quality resulting from inconsistent data can cause customers to lose faith in your brand.

Supplier MDM helps overcome these challenges by consolidating records into a single hub, enforcing governance rules and applying data quality checks in real time. This makes reporting easier, compliance less risky and collaboration across the supply chain more effective.

What Is a Vendor Master File and How Does It Differ From Vendor MDM?

A vendor master file stores the most recent, complete and accurate information about vendors — company names, addresses, tax IDs, payment terms — and is usually maintained in an ERP system. It’s essential but can be limited, since it often grows cluttered with duplicates, outdated contacts and conflicting formats.

Vendor master data management is more than just storing vendor information in a central location, as it lets you actively manage all your vendor master data across multiple systems. This lets you ensure accuracy and consistency, apply governance and connect vendor data to related business processes like procurement, finance and risk management.

What Are the Best Practices for Managing Your Vendor Master File with MDM?

To keep the vendor master file reliable and valuable, organizations should use these best practices with MDM:

- Enforce governance policies: Use consistent formats for addresses, tax IDs and banking details according t your data governance policies.

- Implement identity and access management (IAM): Define clear rules for who can create, update and approve supplier records.

- Deduplicate continuously: Use an MDM tool to detect and merge duplicate suppliers. Your MDM tool should have survivorship capabilities so that the right information is persisted when merging duplicate records.

- Automate validation: Integrate with external sources (tax authorities, watchlists, credit agencies, third-party data providers) to confirm the accuracy of addresses and other verifiable types of data, like credit history.

- Monitor and maintain quality: Establish metrics and dashboards to track data health over time.

These practices make sure the vendor master file stays accurate, trustworthy and capable of supporting procurement, compliance and supplier relationship management.