- Manufacturing Use Case

Optimize Supplier Spend with Supplier 360

How Profisee can help manufacturers further improve and optimize supplier spend through a consolidated global view of suppliers and materials.

Further Optimizing Supplier Spend

Data Domains

Supplier, Material / Part / Component

Business Problem

Difficulty rationalizing suppliers & parts

Teams Impacted

Procurement, Operations, Finance

MDM Impact

Optimized terms, volume discounts, inventory use

Overspending on Critical Components

- Inconsistent discount & payment terms: Different divisions acquire from the same suppliers, but with inconsistent terms negotiated discounts.

- Inconsistent credit terms: Purchases across business lines are made with different credit terms to the same supplier, impacting free cash.

- Inability to negotiate on volume: Without visibility into 100% accurate aggregated spend for each supplier, procurement teams are unable to negotiate optimized pricing and terms.

- Unnecessary purchases: Due to inconsistent data practices across business lines, total material and part inventory is obscured, leading to unnecessary material spend.

Leverage a Supplier 360 for Business Insight

- Consolidate supplier data & terms with supplier 360: Even with multiple ERP and/or procurement spend, MDM creates a consolidated view of suppliers allowing organizations to easily identify inconsistencies and negotiate for optimized terms.

- Aggregate total supplier spend: With a consolidated view of all supplier activity across business lines, procurement can easily and accurate understand total supplier spend.

- Automate part/material cross-referencing: With robust fuzzy matching and machine learning, MDM can identify like parts and materials even when data is inconsistent.

Reduce COGS & Optimize Working Capital

- Negotiate better discounts to reduce COGS: With further optimized discounts, total cost of goods sold is reduced and margins improved.

- Negotiate better payment terms to optimize cash management: With consistent and optimized payment terms, cash management is improved.

- Leverage credit to optimize working capital efficiency: With consistent and well negotiated credit terms, working capital is freed up and cash flow improved.

- Avoid duplicate / unnecessary material spend & excess inventory: With unnecessary and duplicative material and part purchases avoided, capital is freed up, inventory costs reduced, and cash flow improved.

Supplier 360 FAQS

What Is Supplier 360?

Supplier 360 is the idea of having a unified view of all your supplier data. Approaches vary, but most organizations tackle supplier 360 initiatives using either a purpose-built software tool or a master data management tool like Profisee. Some data management software vendors offer supplier 360 tools, but you can also achieve supplier 360 with existing business tools, like CRM or MDM.

How Is Supplier 360 Useful?

Supplier 360 can be useful for a variety of reasons. Many organizations use supplier 360 to:

- Optimize procurement costs

- Speed up vendor onboarding

- Better manage risk

- Reduce unused inventory

- Make progress toward ESG and sustainability goals

- Track vendor performance

For example, with a unified view of supplier data, it’s easier to identify when an organization has more than one contract with the same vendor. This can help the organization consolidate contracts and negotiate a better deal, thereby saving money and making business operations more efficient.

How Does Supplier 360 Work?

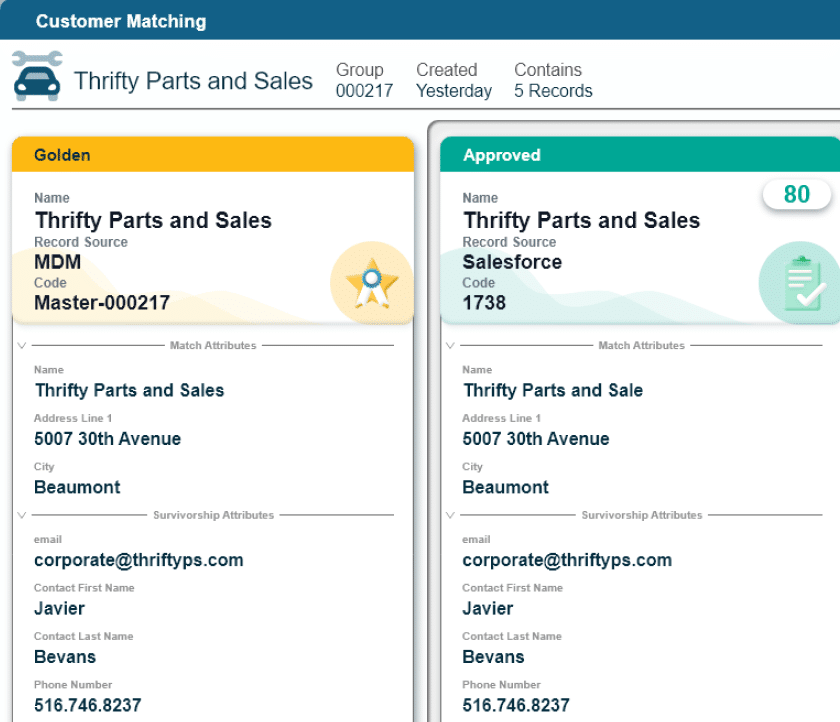

Creating a supplier 360 view typically starts with integrating supplier data from the different sources where it’s stored. It’s not uncommon for supplier data to get stuck in silos, which makes it difficult to derive insights from that data. Using a master data management tool like Profisee, you can integrate supplier data from an ERP, CRM or any other system that might store supplier data.

From there, you can use Profisee to find potentially matching supplier records and merge them, standardizing the data according to your data governance policies. Profisee works with existing data governance tools like Microsoft Purview and Collibra to enforce your data governance policies so that data is consistent, no matter the source.

Once data has been cleansed and standardized, you can make it available to downstream systems that need access to it, like business intelligence or analytics tools. If you’re also using Profisee to master other data domains, this gives you the opportunity to explore relationships between supplier data and other types of data, such as product data, for instance.

Whether you decide to master data from other domains or not, you now have a single source of truth for accurate, up-to-date and standardized supplier data, allowing you to generate trusted insights for driving better business outcomes, like increased revenue, lower COGS and avoiding excess inventory.