- Manufacturing Use Case

Reducing Spend with MRO Master Data Management (MDM)

How Profisee can help manufacturers diagnose manufacturing process inefficiencies to improve oversight and reduce costs.

Reducing Indirect MRO Spend with MDM

Data Domains

Asset, Location

Business Problem

Lost Revenue, Production Disruption, Excess Costs

Teams Impacted

Procurement, Line of Business, Finance

MDM Impact

Matching Duplicate Parts, Automated Workflows

Effects of Inaccurate Indirect MRO Data

- Inventory Overstock: Inaccurate MRO data leads to overstocking of spare parts, tying up capital and warehouse space unnecessarily.

- Downtime & Delays: Incorrect data results in delays in procuring critical parts, leading to unplanned downtime and production losses.

- Higher Maintenance Costs: Lack of accurate asset data results in inefficient maintenance scheduling and increased repair costs due to reactive maintenance practices.

- Compliance Risks: Inaccurate MRO data can lead to compliance issues, such as using incorrect or outdated parts, which may compromise safety and regulatory requirements.

How MDM Can Improve MRO Accuracy

- Data Cleansing and Standardization: MDM ensures that MRO data, including spare part descriptions, vendor details, and inventory levels, is cleansed and standardized across the organization.

- Data Governance: Implementing data governance practices ensures that MRO data is accurate, complete, and up-to-date, reducing errors and improving decision-making.

- Integration with ERP and Maintenance Systems: MDM integrates with ERP and maintenance systems, ensuring seamless flow of accurate MRO data for procurement, inventory management, and maintenance planning.

- Continuous Data Quality Monitoring: MDM includes mechanisms for continuous data quality monitoring and validation, flagging inconsistencies and errors for timely correction.

Business & Financial KPIs Positively Impacted

- Reduced Inventory Costs: By optimizing inventory levels and eliminating overstocking, MDM reduces inventory carrying costs and frees up working capital.

- Decreased Downtime: Accurate MRO data enables proactive maintenance planning, reducing unplanned downtime and improving equipment reliability and uptime.

- Lower Maintenance Costs: Improved maintenance scheduling and resource allocation lead to reduced maintenance costs and increased operational efficiency.

- Increased Production Output: With fewer disruptions and delays, optimized MRO processes supported by MDM result in increased production output and revenue generation.

Frequently Asked Questions about MRO Master Data Management (MDM)

What is MRO master data management?

MRO Master Data Management (MDM) refers to the practice of creating, maintaining and governing high-quality data related to maintenance, repair and operations (MRO) within an asset- or manufacturing-centric organization. This includes data about equipment, spare parts, suppliers and maintenance procedures. By standardizing and centralizing this information, MRO MDM ensures that businesses operate with a single, accurat, and trusted source of information across all systems. This approach is critical for improving data-driven decision-making and reducing operational inefficiencies.

Explore how data governance frameworks are foundational to enabling successful MDM initiatives, including those focused on MRO.

What does MRO MDM involve?

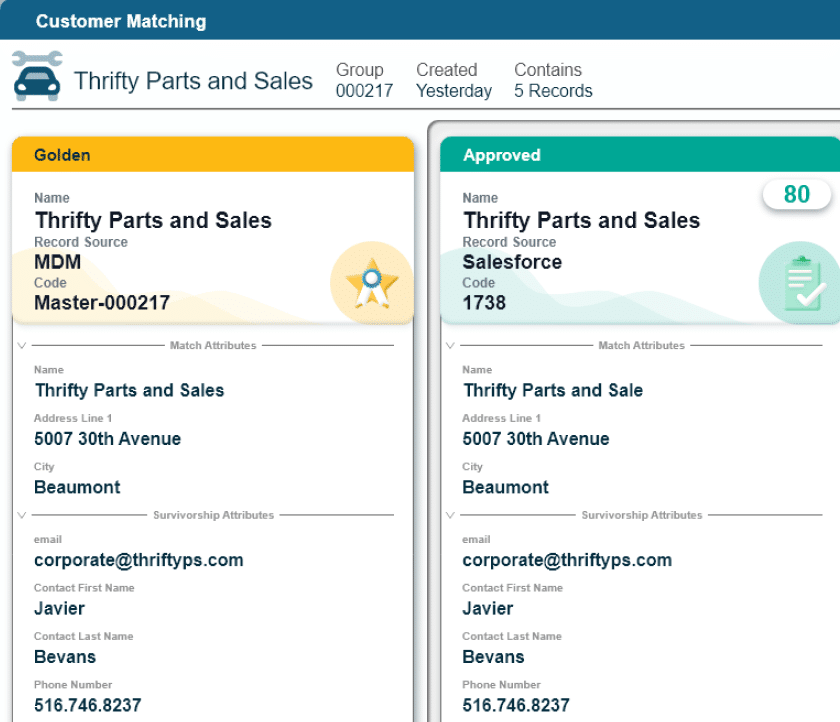

MRO MDM involves several key processes that ensure data accuracy, consistency and usability across the organization. First, it starts with data cleansing and standardization—eliminating duplicate records, normalizing naming conventions, and validating information about parts, suppliers, and maintenance schedules. This ensures all departments are using the same terminology and referencing correct data.

Second, it includes data governance policies, which establish clear rules and accountability for managing MRO data. Organizations also integrate MDM with enterprise resource planning (ERP) and computerized maintenance management systems (CMMS) to streamline workflows and enable seamless data sharing between systems.

Finally, MRO MDM requires ongoing monitoring and continuous improvement, leveraging tools like data quality dashboards to track and address discrepancies over time. Learn more about how data integration facilitates better connectivity between MDM systems and other enterprise platforms.

What are the benefits of MRO MDM?

MRO MDM delivers significant benefits to organizations, primarily through cost reductions and operational efficiencies. By ensuring accurate and complete data, companies can optimize inventory levels, avoid overstocking and reduce carrying costs, ultimately freeing up working capital. With better data, organizations can also minimize unplanned downtime by improving preventive maintenance schedules, enhancing overall equipment reliability.

Furthermore, improved data visibility streamlines procurement processes, allowing organizations to consolidate supplier relationships and negotiate better pricing. The result is not only reduced maintenance costs but also better alignment between operational and financial goals. For more insights into the advantages of centralized data, check out how MDM improves analytics and decision-making.

Why is MRO master data management useful?

MRO Master Data Management is essential for any organization looking to enhance operational performance while controlling costs. Accurate MRO data allows teams to make better-informed decisions, whether it’s planning maintenance activities or managing inventory more effectively. With a single source of truth, organizations can eliminate inefficiencies caused by data silos and inconsistencies, resulting in reduced downtime, fewer stockouts and faster procurement cycles.

Additionally, MDM enables businesses to adapt more quickly to changing operational demands by providing the foundation for data-driven strategies. Implementing effective MRO MDM practices also aligns with broader organizational goals like improved compliance and risk management. Learn more about the broader role of MDM in digital transformation.