Table of Contents

- Harmonizing Analytics Across Multiple ERPs with Master Data Management

- Trust Your Manufacturing Insights with High-quality Data

- Augment an ERP Migration with Master Data Management

- MDM and ERPs: Better Together for Manufacturing

- Read the Full Guide on Manufacturing Data Strategy

- Break down enterprise data silos

Manufacturers understand the struggles of managing and overseeing operational business processes on a daily basis. Ensuring that production runs smoothly and efficiently while monitoring supply chain issues and anticipating market shifts is no easy task. This is where managers often rely on integrated enterprise resource planning (ERP) systems to automate those processes and standardize operational dependencies.

According to Gartner, ERP is defined as the ability to deliver an integrated suite of business applications. Although ERP tools remain useful for large-scale industries like financial services and HR, they share a common process and data model covering end-to-end operations found in distribution, service and supply chain. And ERPs can help optimize and augment these processes to help manufacturers succeed in today’s challenging business climate — but only if they can base these decisions on high-quality data.

For an ERP system to truly bring value to your business, you need a clean and accurate data estate delivered by master data management (MDM).

Harmonizing Analytics Across Multiple ERPs with Master Data Management

Manufacturers often grow through acquisition, taking on smaller organizations’ production and IT environments. But expanding operations this way can often accumulate multiple instances of the same ERP or often multiple different systems, leading to complex sprawl of systems that can’t communicate in real-time.

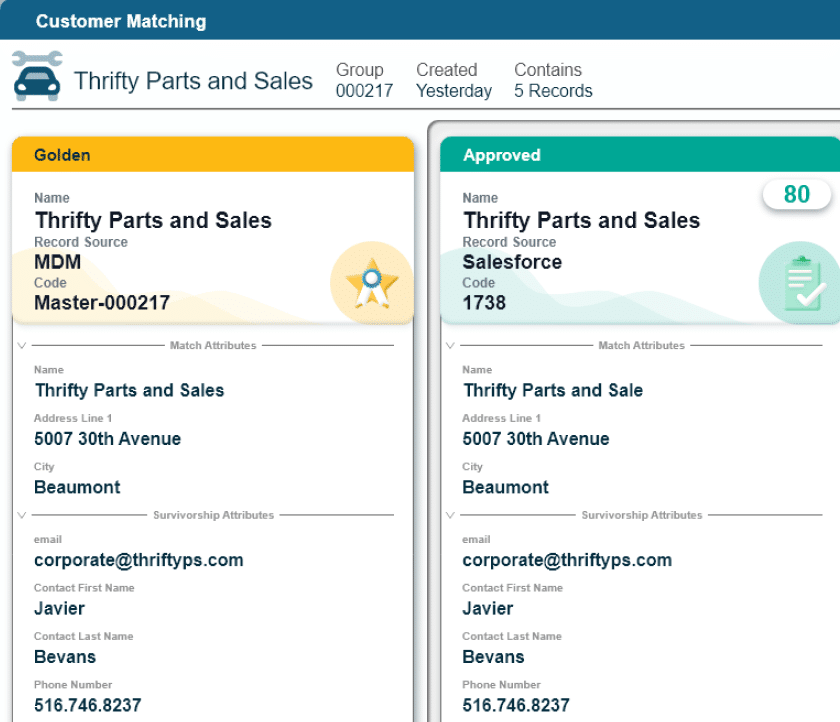

Unfortunately, this prevents a ‘single view’ of your key metrics and insights that are actually being analyzed — suppliers, vendors, parts, assets, etc. MDM helps to create a single, trusted data foundation that enables you to view analytics across multiple ERPs and sync trusted data back to source systems, keeping data clean for the long term.

With the daily manufacturing workflow having so many moving parts, it is important for analytics to remain visible and accurate when keeping up with the market and overseeing a resilient supply chain. This also means that there is data outside of your ERPs and data systems — including in CRMs, databases or other systems. By connecting your many data sources and enforcing data quality standard, you can put trusted data in the hands of business users who need it, including automated reporting and analytics.

You can’t deliver value by leveraging bad data. When MDM works alongside your ERP system(s), accessible and reliable analytics are at your fingertips.

Trust Your Manufacturing Insights with High-quality Data

As previously mentioned, ERPs typically only work with the data natively entered in that specific system. To get a full, holistic understanding of your business, you need to understand the data accumulated across your enterprise, including data outside your ERP.

According to a 2022 survey from McKinsey & Company, supply chain leaders with high-quality master data were 1.5 times more likely than their peers to report no challenges from the 2021 supply chain impacts. MDM integrates and enriches data from any source to provide manufacturers with a complete view of their customers, prospects and partners.

Business value is derived from having a complete understanding of your raw materials, suppliers and production elements. MDM provides the clean and consistent data necessary to make that a reality.

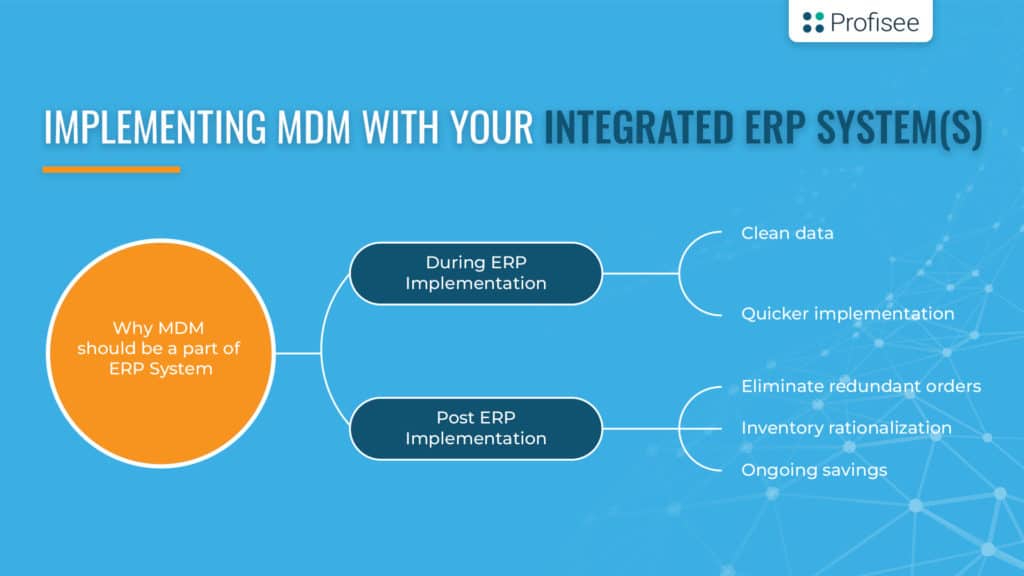

Augment an ERP Migration with Master Data Management

As manufacturers growth through acquisition and take on additional “technical debt” in the form of multiple ERP systems, many manufacturers see the solution as consolidating their litany of systems into a single, cloud-based ERP.

While that will undoubtedly consolidate much of your manufacturing data and provide quality-of-life improvements through using newer systems, this can take years and cost you millions, only further delaying your strategic initiatives.

It’s important to leverage your data with a platform that focuses on your data quality regardless of the source system. An integrative MDM platform connects any ERP with technologies and applications you already use in months rather than years. It breaks down data silos to match and merge data from any source to provide a singular resource hub for your most critical data.

Implementing MDM saves yourself the opportunity costs that come along with further delaying your projects, campaigns and initiatives. This modern approach to managing your most critical data offers a viable data solution without the drawn-out processes and financial burdens.

And when you do ultimately decide to consolidate or migrate your ERP systems, your MDM platform can easily interface with this new system to ensure your newly stored data remains clean and accurate so you can deliver measurable value for your organization.

MDM and ERPs: Better Together for Manufacturing

MDM helps to eliminate the damage caused by data inaccuracies, inconsistencies and disparities across your data estate. With manufacturers relying heavily on real-time insights and accurate information to anticipate consumer demands, rising market trends and inventory levels, there is no room for cracks in your data foundation.

Supporting your ERP systems with MDM means you no longer have to worry about where the data is entered and stored, allowing you to focus on enhancing the data’s quality and significance within your organization. By implementing an integrative MDM platform with your established ERP systems, the two can work together to digitally transform your business so you can finally achieve your strategic business goals with actionable data.

Read the Full Guide on Manufacturing Data Strategy

Optimizing your ERP and delivering substantial business value for your organization requires a smarter, more modern approach to managing your manufacturing data. Read the Complete Guide to MDM for Manufacturing below to learn how you can finally overcome the data-quality issues standing in the way of your strategic initiatives.

Break down enterprise data silos

Forrest Brown

Forrest Brown is the Content Marketing Manager at Profisee and has been writing about B2B tech for eight years, spanning software categories like project management, enterprise resource planning (ERP) and now master data management (MDM). When he's not at work, Forrest enjoys playing music, writing and exploring the Atlanta food scene.