Table of Contents

- What Is Supply Chain Data Management?

- Why Is Supply Chain Management Important?

- How Is Supply Chain Data Collected?

- 7 Steps of Supply Chain Data Management

- How Is Data Used in Supply Chain Management?

- What Is Supply Chain Analytics and How Does It Connect to Supply Chain Data Management?

- What Are the 5 Types of Supply Chain Analytics?

- What Is Big Data in Supply Chain Data Management and How Does It Affect It?

- Benefits of Using Profisee's MDM with Supply Chain Data Management

- Power Your Supply Chain Data Management Initiative With Profisee

Key Takeaways

Supply chain management is a complex process that involves identifying source systems that record supply chain data, aggregating and integrating that data into a central repository, cleansing it and making it available for use by other systems like business intelligence, supply chain management (SCM), ESG reporting tools and others.

Effective supply chain management can have a massively positive impact on the organization, helping to grow revenue, negotiate better deals with vendors and improve vendor relations, reduce waste in the supply chain, lower carbon emissions and improve customer satisfaction.

Due to the large volumes of data involved, supply chain data management is often closely tied to an organization’s Big Data initiatives. Master data management (MDM) can play an important role here by creating golden records of supply chain data that people across the enterprise can trust and rely on for accurate reporting and improved decision making.

Improving today’s supply chain requires data wrangling on a large scale, bringing together vendor, customer, sales, supply, manufacturing, shipping and storage. While supply chains have been improved through IoT, sensors and barcodes, the digital noise produced by all these programs can make analysis and optimization difficult.

And supply chain professionals know it, with 79% citing visibility as their top supply chain priority, and 80% of supply chain pros stating they need data analytics to make informed decisions.

Supply chain data management seeks to simplify, organize, make visible and analyze that data for all stakeholders to improve performance and the bottom line.

The State of Master Data Management (MDM) 2026

What Is Supply Chain Data Management?

Supply chain data management is the process of collecting, organizing and analyzing data points throughout the complete supply chain from raw materials through returns. Data management for supply chains also deals with the storage and deprecation of data when it’s no longer needed.

Why Is Supply Chain Management Important?

Whether a company has an established supply chain or needs to plan the optimal supply chain for an upcoming product, supply chain management can:

- Improve customer and supplier relationships.

- Increase fraud detection.

- Lay the groundwork for fewer disruptions and faster pivots.

Supply chain management seeks to make all parts of the supply chain visible so manufacturers can react to current situations, spot risks and plan for future disruptions.

Data management is a critical part of the supply chain management process, as most companies have undergone digital transformations that remove the need for paper invoices and shipping manifests. While we’re all saving a little on paper products, the data these digital trails create needs oversight and analysis that moves the company toward optimized workflows.

How Is Supply Chain Data Collected?

Supply chain data comes from many sources, including those from inside the company and external sources like vendors, partners and stakeholders. Some example sources of supply chain data include:

- IoT devices, sensors and barcode scans to show the location of shipped materials.

- Shipping manifest documentation that moves with materials and parts through the supply chain.

- Invoices for work or supplies.

- Surveys and feedback from employees and stakeholders.

- CRM software with customer, sales and vendor information.

- ERP software with financial, logistical and operational data from across the enterprise.

- Supply chain management (SCM) software designed to integrate data from partners.

Depending on the goals of the company and the technical capabilities of the team, supply chain data may come to a central storage tool like a data lake or data warehouse.

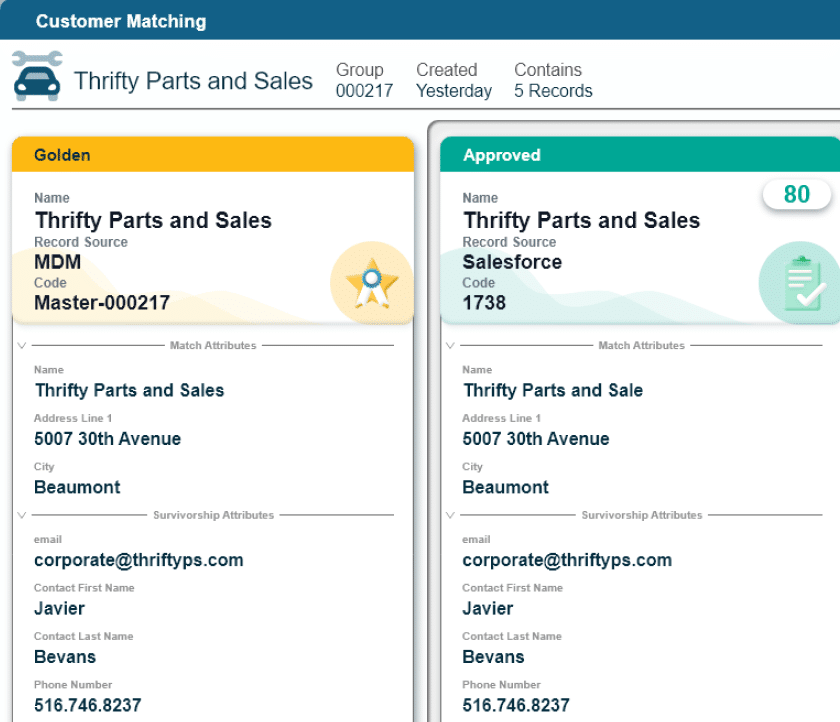

These records must be deduplicated, enhanced to make up for missing fields, and transformed into formats usable by analytics and forecasting software. We call the cleansed and usable data that results from collection and processing golden record data, as it is the most up-to-date and trustworthy information in the system.

7 Steps of Supply Chain Data Management

Supply chain data management should work in concert with your supply chain management initiatives, which should roll up to larger business objectives. A data management strategy without clear goals and measurable outcomes will quickly become chaotic if not unusable. Follow this seven-step supply chain data management process:

1. Outline Your Supply Chain Data Strategy

Work backward from your business objectives to one or two high-impact goals for the data initiative, like “Reduce time to market by improving just in time delivery for 20% of vendors” or “Improve margins on supply by 5% in Q3.”

Planning at this stage also includes documenting expected outcomes as SMART goals, identifying critical stakeholders within supplier and internal groups and outlining potential internal risks and contingency plans. For changes in supplier, shipping or storage rates and capabilities, build lists of potential alternatives.

2. Align Internal Teams and Vendors

Without communication and transparency between the organization and all external stakeholders, the company can’t collect the data it needs. Transparency between vendors and suppliers as well as internal stakeholders across the business builds trust while allowing SMEs the chance to identify risks hidden to the data team and respond to issues in time to pivot. Consult with logistics teams, for example, on what data they will and won’t share with the organization, and be sure to emphasize how this collaboration will improve outcomes across the board.

3. Collect Data Sources

Catalog data sources from across the organization and suppliers. In addition to finding out the name and purpose of the tools the stakeholders use, ask how that data is currently accessed and what other options are available for each of those sources. No need to do manual CSV uploads when you can get more information quicker with an API connection.

4. Integrate, Standardize and Deduplicate Data Across the Supply Chain

Follow established frameworks for master data management and Big Data management in order to build your organizational plan. Start with the most crucial data points and build out your data plan piece by piece. For instance, you may want to standardize vendor and supplier information across all platforms and follow that with product information.

5. Choose Scalable and Secure Storage Aligned to Analytics Goals

Data storage should align with the strategic business goals and future plans for data. Consider options that add scalability to new partner suppliers or new manufacturing lines and security for intellectual property and data. Research what data storage types will work best for your existing data and goals and that will integrate with the current systems.

6. Apply Analytics Tools to Generate Supply Chain Insights

The data you organize and store doesn’t help optimize your supply chain if you can’t analyze it. Choose from a wide variety of data visualization, dashboard or reporting tools available on the market, but again, consider the scalability and capabilities of the solution in comparison with your goals and objectives.

7. Use Supply Chain Data Insights for Improvements

Put your analysis to use by making incremental changes in your supply chain that work toward your goals. If your goal is to source more sustainable raw materials suppliers, make sure you’ve pulled sustainability data from partners and third-party data brokers and that your findings guide decisions for future partnerships.

How Is Data Used in Supply Chain Management?

Data is a critical piece of supply chain management, as it makes up the dashboards, reports and analytics that help the company optimize their supply chain. These are just a few examples of supply chain data types and how they can be used to improve outcomes.

| Data Type | How It’s Used |

|---|---|

| Material and shipment location data |

|

| Logistics routes and cargo manifests |

|

| Inventory and warehouse levels |

|

Real-time data helps manufacturing companies understand the current circumstances and pivot quickly, if necessary. Aggregated historical data can be used to spot trends in performance of products and stakeholders, including seasonal changes and one-off spikes.

Predictive data extrapolates from the historical data and can be combined with third-party data (weather sources and economic sources, for example) to identify risks and improvements that would impact the bottom line. Combining individual types of data from various sources and times results in increased revenue and performance as well as increased customer satisfaction.

What Is Supply Chain Analytics and How Does It Connect to Supply Chain Data Management?

Supply chain analytics is the use of data to identify inefficiencies and optimize operations of the supply chain. But analytics is only as good as the data behind it. Robust supply chain data management programs like MDM support and supply the supply chain analytics teams by standardizing data into usable and reliable forms for analysts.

A recent report showed that data scientists spend 80% of their time readying data for analysis; performing de-duplication, schema standardization and data transformation to make data usable. A well-planned and executed supply chain data management strategy can reduce that statistic.

What Are the 5 Types of Supply Chain Analytics?

Supply chain analytics follow established data analytics forms and use data sets from the organization and partners. Access to this wealth of information can help analysts make some interesting discoveries that wouldn’t be available through analysis of only the organization’s data. The five types of supply chain analytics are:

- Descriptive: This analysis describes the current data situation. It’s used for reporting on what has happened in the data history of the supply chain to understand the current state.

- Diagnostic: This analysis diagnoses problems or issues with the supply chain based on the current data, such as late deliveries or manufacturing slow-downs.

- Predictive: Predictive analytics attempt to describe future supply chain events based on current data and potential contingencies.

- Prescriptive: Prescriptive analytics seeks to provide answers and suggestions for future actions based on current data. This type of analytics prescribes actions that suppliers, manufacturers and vendors should take.

- Cognitive: Cognitive analytics applies AI and ML models to manufacturing data to understand and make projections about future situations.

While all of these data analysis types have their place, cognitive analysis may hold the most promise — not because it’s more reliable than the other methods, but because it can calculate large amounts of data quickly.

What Is Big Data in Supply Chain Data Management and How Does It Affect It?

Big Data is a term used to describe the practices of collecting, managing and putting the data a company generates to use. In the context of supply chain data management, Big Data comes from the sources we covered earlier (IoT devices, shipping manifests, CRM and ERP systems and supply chain management software systems) and is used to help optimize supply chains.

Big Data initiatives often use data lake, data warehouse and master data management (MDM) tools to manage and store data between the source systems and downstream systems like analytics and AI. Doing this helps companies unlock previously hidden insights and identify opportunities to make their supply chains more efficient, resilient and sustainable.

Harnessing Big Data can help you detect connections in your supply chain that weren’t apparent before. For instance, with a more unified view of your supply chain operations, you might be able to consolidate shipments to lower the company’s carbon footprint. Big Data also opens the door for implementing machine learning to analyze weather patterns and ocean traffic data to identify less congested and faster shipping lanes.

Benefits of Using Profisee’s MDM with Supply Chain Data Management

MDM software and supply chain data management work together to build a reliable vision of the company’s supply chain. MDM methodologies cleanse and transform data for storage as the golden records for suppliers, vendors, manufacturing processes, and other slow-changing data. These golden records, combined with real-time numbers or locations enable quick routing decisions to stores based on accurate location and shipping information. Or team members can find an approved supplier without needing to go through many layers of approvals.

Profisee MDM helps companies harness the power of their master data, and supply chain master data management builds the foundation on which an agile and responsive supply chain is built.

| Benefit | MDM | Supply Chain Data Management |

|---|---|---|

| Improved customer relationships | Yes | Yes |

| Operations improvement | Yes | Yes |

| Risk management | Partially, must be paired with data security/governance | Yes |

| Product quality | No, focuses on data usability instead of product quality | Yes |

| Unified data view | Yes | No, missing HR and can lose key sources based on format |

| Forecasting | Yes | Yes |

Power Your Supply Chain Data Management Initiative With Profisee

With Profisee, it’s easy to integrate all your supply chain data from disconnected systems and create trustworthy golden records for strategic initiatives like supply chain optimization, better compliance and reporting and more insightful analytics.

Tamara Scott

Tamara Scott is a writer, editor and content strategist with over a decade of experience located in Nashville, TN. Tamara holds a Master's in English from Belmont University, formerly served as Director of Content for TechRepublic, and her work has appeared in ServerWatch and EPI-USE.com, among others. When she's not crafting SEO-informed and conversion-ready content for SaaS and IT service companies, she's probably at home on her pottery wheel. Connect with her on LinkedIn.