Understanding the pressure today’s manufacturing companies face from pandemic to profitability is the focus for this session on data management for modern manufacturing. Learn from Michael Watson of Microsoft, Martin Boyd of Profisee and experienced MDM practitioner, Ken Squires for specific steps you can take to put in place a trusted data foundation to increase agility and effectiveness. Thank you to Avanade for help in hosting this web session today.

Listen to the Podcast!

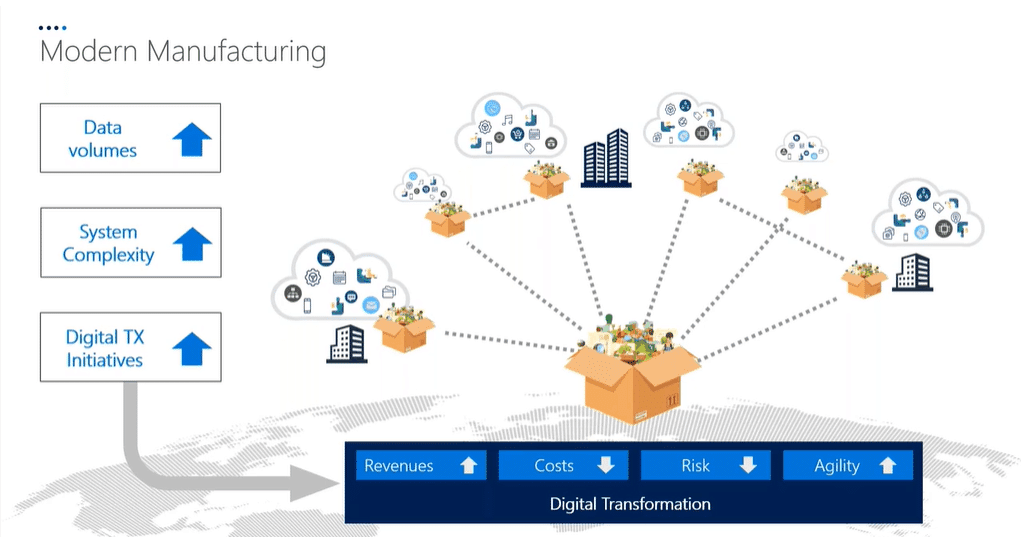

Demands on Manufacturers Ever Increasing Today

Today’s manufacturers are increasingly facing tougher environments in which they must continue to grow revenue, reduce costs, mitigate risk and drive agility as they look for additional ways to disrupt the old ways of doing things and innovate for today’s economic realities with a global pandemic thrown in for good measure! A trusted data foundation is a must have to survive and thrive today.

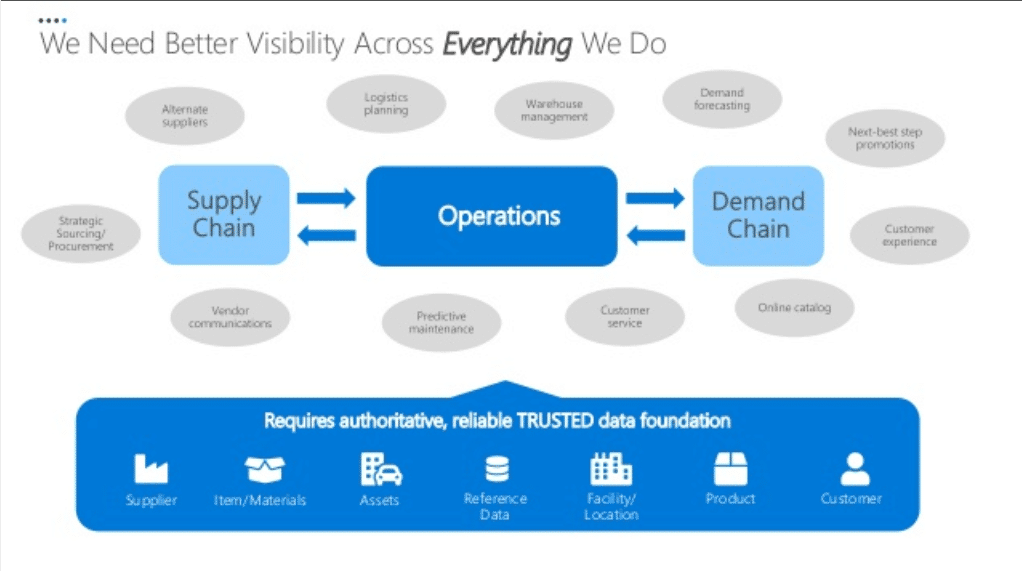

Manufacturers need better visibility across everything.

Microsoft and Profisee work together to help support the efforts manufacturers are working on today to modernize the way data is managed to support these business initiatives.

“Supply chain performance is dependent on consistent definitions of customers, products, items, locations and other master data objects. When data is poorly governed and inconsistent, supply chains become less competitive…” Andrew White, Gartner.

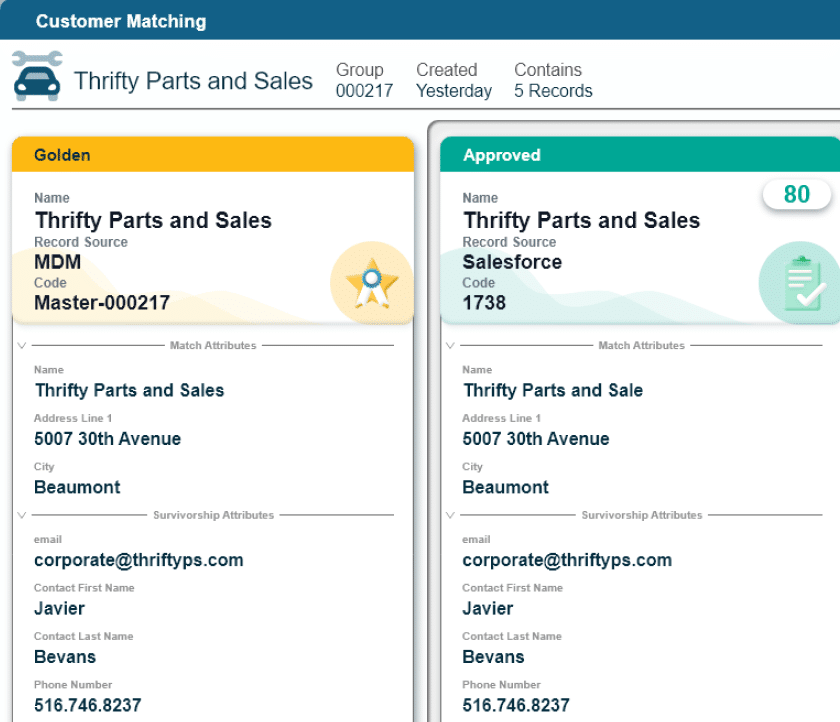

At Profisee, we see these common areas to include in the manufacturing data foundation:

- Supplier

- Item/Materials

- Assets

- Reference Data

- Facility/Location

- Product

- Customer

Of course, you can manage any domains or grouping of information that are important to you. But having a core competence of data management for these domains within your company means you have the ability to answer key questions. Questions such as ‘which are our most profitable customers or vendors?’ or ‘how much do we buy from these vendors?’ or ‘what is the risk to our supply chain if we have a manufacturing delay in our top 10 most popular products?’.

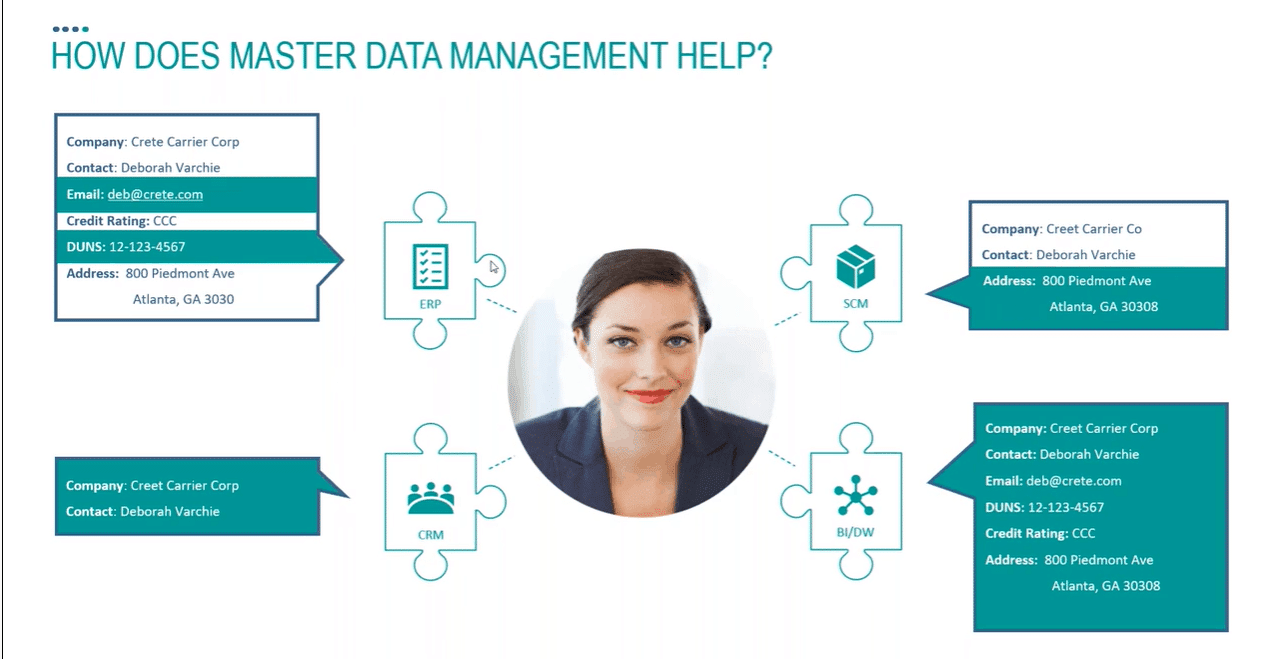

Some of these questions may seem basic, but when the accurate data you need is stored in 10 or 20 different places all with different naming conventions — you can see it is very hard to accurately answer the questions, and certainly very difficult to do so with any degree of timeliness and accuracy.

Example: How master data management can help

Next, we hear from Ken Squires, a manufacturing industry executive.

Ken has worked with clients as a consultant for E&Y and other consulting firms, as well as an extensive career at ITT, where he was able to set up their analytics and MDM programs & technologies.

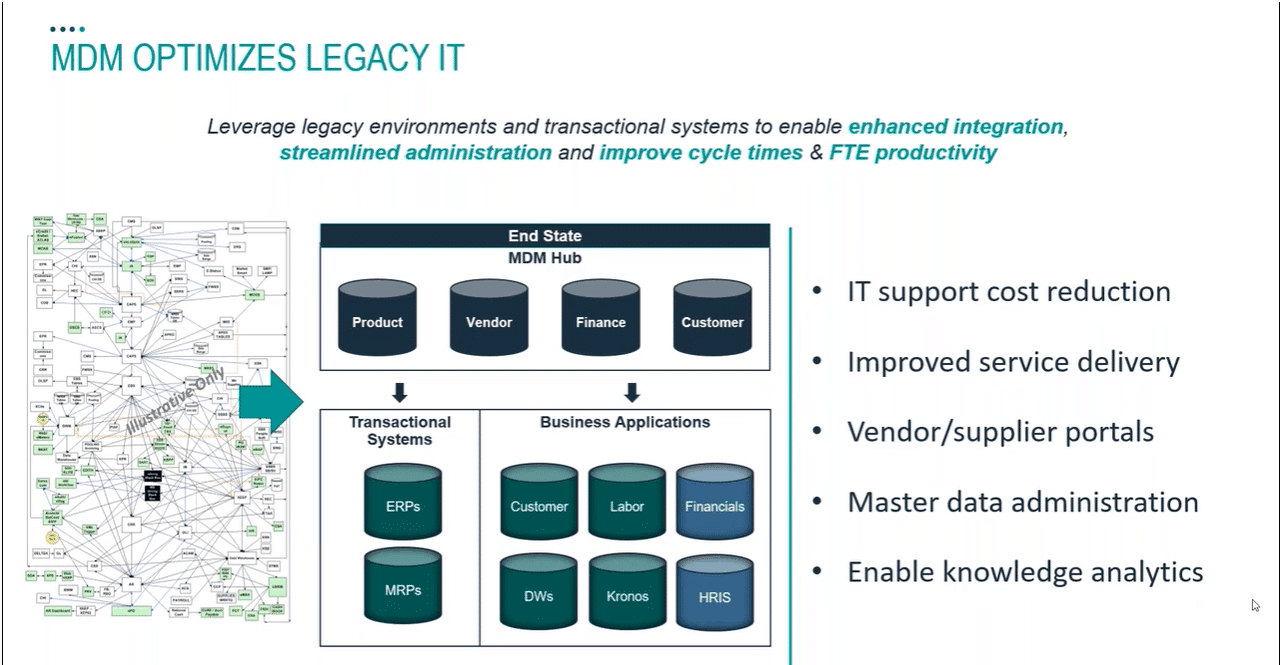

Ken recommends making sure that you understand the landscape within your company to establish a framework for MDM success. You need to understand where you are starting from so that you can build the business case for starting and growing the use of MDM as a strategic methodology. Here’s a great example of some of the ways Ken has helped use MDM to optimize legacy IT applications:

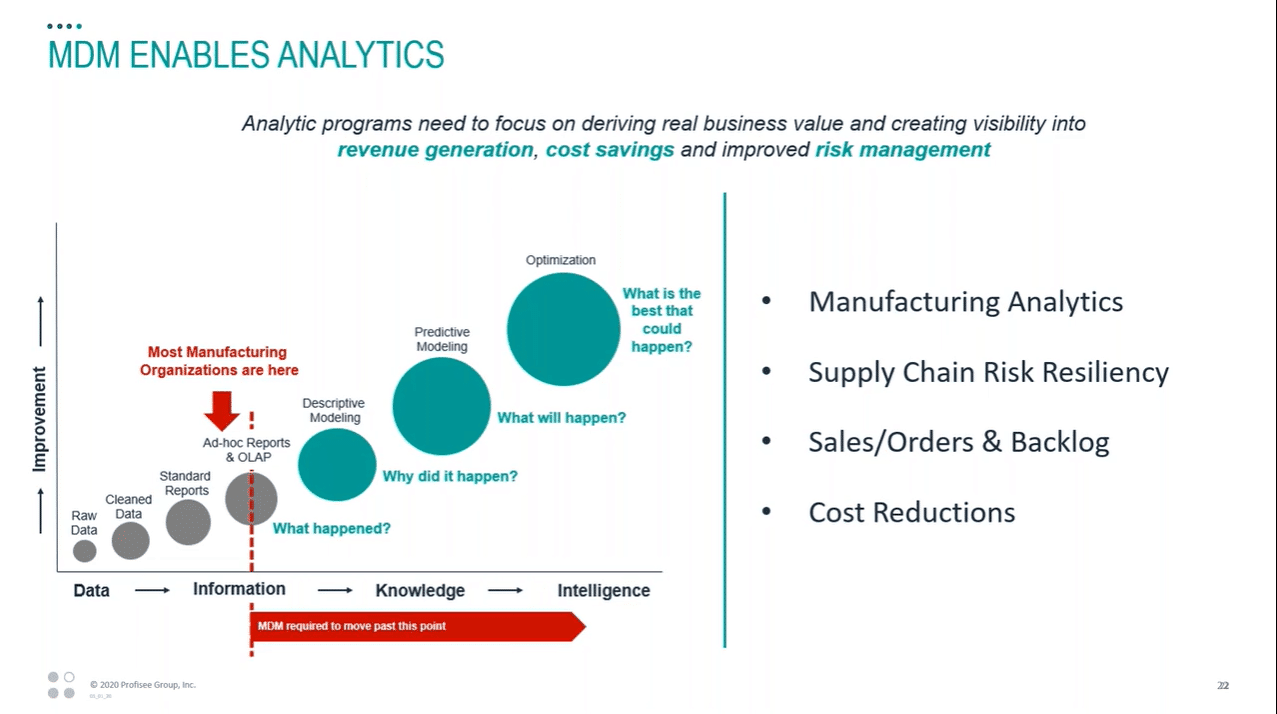

Next after getting the technical aspects of capturing the data, managing the data to improve service delivery, reducing IT support, and helping support SAP implementations across 5 different divisions – it was time to think about how to use MDM to enable effective analytics and drive revenue generation, cost savings and improve the ability to manage risk across the supply chain even including overtime management.

Hard won lessons learned over time

- More domain coverage is better

- Enable the business to own responsibility for the master data

- Focus on real business problems that can be solved

- Leverage and build on having MDM as a part of a bigger program and then spin out MDM to solve additional problems

- Plan to build incrementally, share quick wins and scope for the future

In summary, we learned:

- Manufacturing is demanding

- Data volumes

- System complexity

- Need visibility across it all

- MDM fills a gap

- Use cases drive value

- More domains enable more use cases

- MDM becoming a required core competence

- Leading practitioners

- Building trusted data foundation across domains

- Drive business efficiencies & eliminate redundancy

- Standardize data to drive specific use cases

As you continue on your MDM journey in the manufacturing space, these are some excellent examples of ways to get started today.

Interested in learning more? Download a full copy of the guide below.

Forrest Brown

Forrest Brown is the Content Marketing Manager at Profisee and has been writing about B2B tech for eight years, spanning software categories like project management, enterprise resource planning (ERP) and now master data management (MDM). When he's not at work, Forrest enjoys playing music, writing and exploring the Atlanta food scene.