Table of Contents

- What Is Supply Chain Visibility?

- Types of Supply Chain Visibility

- How Does a Highly Visible Supply Chain Work?

- What Are the Supply Chain Visibility Challenges?

- What Are the Benefits of Supply Chain Visibility and Why Is It Important?

- What Is Poor Supply Chain Visibility?

- 5 Steps on How to Increase Supply Chain Visibility

- Examples of Supply Chain Visibility

- What Are the Differences Between Supply Chain Visibility and Supply Chain Transparency?

- Supply Chain Visibility Trends in 2025

- What Should You Look for in Supply Chain Visibility Tools?

- Increase Supply Chain Visibility with Profisee

Key Takeaways

Good supply chain visibility provides benefits like increased revenue, improved brand perception, high rates of customer satisfaction, more sustainable operations and better financial reporting for multiple industries, such as manufacturing, food production and consumer packaged goods (CPG).

Supply chain data comes from a wide variety of sources, including internet of things (IoT) devices, ERP systems, supply chain management (SCM) systems and more.

A number of different software tools exist to help you gain more visibility into your supply chain, from dedicated SCM tools to master data management (MDM) tools like Profisee.

A supply chain that can react quickly and smoothly to changing market and environmental factors increases revenue and decreases costs for most companies and manufacturers.

That’s what supply chain visibility offers. Yet, many companies fall short of full visibility because of a lack of planning, communication and data. This guide explains what optimal supply chain visibility looks like and how you can achieve it.

The 2025 Data Hero Summit

What Is Supply Chain Visibility?

Supply chain visibility is the ability to access and integrate data from all parties within the supply chain and use that data to make strategic business decisions.

Supply chain visibility requires data transparency and business cooperation between stakeholders throughout the supply chain, from raw materials through shipping and returns.

Types of Supply Chain Visibility

Depending on business needs and strategic goals, supply chain visibility’s focus should shift from business to business. While some companies may want strict record-keeping for environmental health and safety (EHS) initiatives, others may hope to primarily increase revenue and reduce overhead costs. The most common types (or focuses) of supply chain visibility include:

- Audit and Regulatory (Compliance) Oversight

- Activities (Process) Documentation Visibility

- Supplier/Partner Visibility

- Cost Analysis and Financial Visibility

Audit and Regulatory (Compliance) Oversight

When fully implemented, supply chain visibility creates complete and accurate records of transactions, including RFPs, invoices, sales sheets, transfer receipts and even customer contact logs throughout the supply chain. These records become searchable for outside auditors and compliance officers, which makes customer data privacy requests, environmental sustainability reports and financial audits easier to produce and analyze. A streamlined documentation process saves the company from unnecessary regulatory fines and time lost to unearthing documentation siloed within departmental storage.

Activities (Process) Documentation Visibility

Supply chain visibility logs and classifies each action performed by all parties along the supply chain, making those activities available for analysis. This transparency helps managers and individuals:

- Improve internal processes

- Communicate with internal and external stakeholders about upgrades

- Track and improve upon safety concerns or violations

When activities and processes are visible, every member of the supply chain organization can identify and implement process improvements.

Supplier/Partner Visibility

Companies looking to optimize their logistics must gather data on the shipments, storage and delays along the supply chain. This requires supplier information management in addition to shipping and warehousing vendors to understand the speed of sourcing and production versus the time in transit and time spent waiting for transfer. Logistical teams, sales, manufacturing and leadership all rely on inventory and sales numbers to ensure balanced production. Supply chain visibility helps companies pinpoint and advise partners on cooperative optimizations that improve speed and time to market for all involved.

Cost Analysis and Financial Visibility

Supply chain visibility designed to improve cost analysis works similarly to a logistical focus, but with an emphasis on money rather than time, and is performed primarily by management, leadership and financial departments. Cost analysis can help companies pinpoint better vendors, react to political or environmental contexts that may increase costs and reduce inventory overages or return rates.

How Does a Highly Visible Supply Chain Work?

A highly visible supply chain tracks, documents and assesses the fit and improvement potential of all parts of the supply chain. This requires data integration, standardization, deduplication and analysis from a variety of sources.

Raw Materials

Producers and suppliers supply sourcing, processing and storage data like location, temperature and quality control checks data. This information is used to verify quality of raw materials, and will be carried with the product throughout its lifecycle.

Transportation

Providers move materials, parts and products along all parts of the supply chain. These providers submit data on raw materials shipping, ingredients transloading and warehousing location and conditions records that inform manufacturing processes in the next step of the chain. This information should also be used down the chain to regulate raw materials supply to prevent over-ordering.

Manufacturing

Manufacturing plants supply data related to location, batch numbers, quality control and anomalies from the processing and production of items. Quality and process information is passed back down the chain to transportation and raw materials to identify areas for optimization. Production numbers along with all data from raw materials and transportation travel up the chain to packaging.

Packaging

Packaging suppliers document sources of products (with all attached manufacturing, transport and materials data) plus printing batches and materials that go into the item packaging. Numbers and emerging quality information are passed down the chain, while all previous data moves with the product up the chain.

Inventory

Stores and warehouses report on sales numbers and shelf levels along with expiration dates, storage conditions and product locations. All of this information — along with all preceding records — goes back to sales, finance, marketing and home office teams.

Returns

Returns data closes out the cycle by providing customer satisfaction, reshelving, restocking, quality assurance and defect data back to home office and out to relevant departments.

Depending on the product and industry, other supply chain sources may be necessary, especially for highly complex or highly regulated industries like technology, oil and gas, food and beverages or pharmaceuticals.

What Are the Supply Chain Visibility Challenges?

A supply chain visibility strategy requires you to communicate with internal and external stakeholders in ways that may not have been necessary in traditional supply chains. This new communication will focus on reliable data, transparency and technology.

Operationally, unreliable data coming from multiple sources will cause confusion and slow-downs rather than intended speed. Lack of transparency from one or two partners gives an incomplete data picture, creating gaps in analysis and understanding. And outdated or uncooperative technology will result in manual processes that add more complexity instead of reducing it. We go into specifics on these challenges, and sample ways to combat them, below.

Data Usability

In order for your team to build a highly visible supply chain, you must focus on collecting and transforming data from many different sources into usable data. It’s not enough to connect all available data sources to the centralized technology like an ERP or data analytics tool, as that raw data will take many forms. When data formats don’t match, they cannot be combined, deduplicated or analyzed consistently across the board.

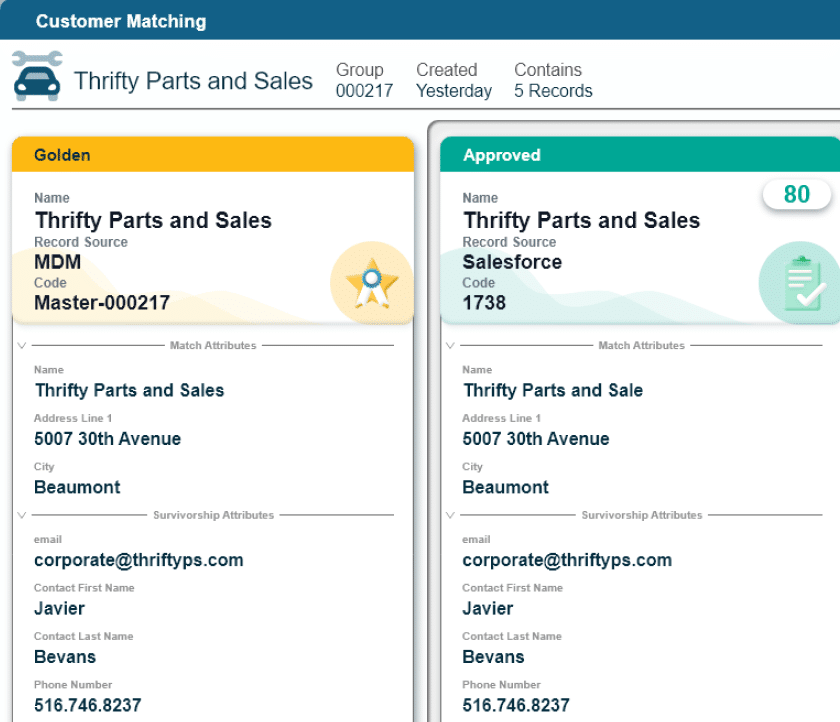

An MDM for manufacturing and supply chain visibility strategy can help the organization agree on data domains, formats, cleansing methods and transformation options that will make data more usable in the final product.

Transparency

A major challenge for many organizations looking to implement a supply chain visibility strategy comes from the unwillingness of other departments, partners and stakeholders to share their data. Many of these concerns come from long-held beliefs that data holds a competitive advantage, but can also stem from risk management and data security concerns. Additionally, companies may just not want you to see how disorganized their data landscape is internally.

To help overcome these data silos, you may need to engage in some education and frank communication about the purpose of visibility with these partners. Listen to their fears, discuss greater objectives and try to understand the underlying reasons that support their fears. Communicate with the partners on what data can and should be shared, which data points they can keep private and try to come to an agreement that will serve everyone.

Technology

Technology implementation and deprecation cause stress (even panic!) within organizations because whether the tech people use is the best option or not, changing to a new system requires change. At the same time, tools that can’t communicate across departments create more work for individuals and less visibility into supply chain status.

It’s a good idea to plan for and implement change management systems alongside the technology onboarding. Change management can help users understand and get used to new systems quickly and increase adoption of the new systems among stakeholders clinging to old systems. While change is painful, remind partners of the benefits these new systems offer and how working in a highly visible data landscape can improve products, revenue and brand strength.

What Are the Benefits of Supply Chain Visibility and Why Is It Important?

Supply chain visibility improves workflows for all stakeholders, helps teams find and understand inefficiencies and grows revenue across the board. Three major areas where a visible supply chain impacts growth include inventory, finance and brand.

Smarter Inventory Planning

A visible supply chain helps companies maintain a balanced inventory that’s responsive to supplier, demand, environmental and political changes. With a data-informed approach to inventory, businesses can reduce their warehousing overheads and increase just-in-time logistics metrics.

Proper inventory analysis paired with third-party and partner data also improves forecasting and demand management, moving balanced inventory from a one-off event to the business status quo.

Stronger Financial Performance

Finance teams love a visible supply chain for its audit and analysis capabilities. A digital paper trail comes standard with visibility, which in turn makes for more accurate billing, reduced overages and stockouts and increased revenue.

Supply chain visibility also impacts risk management for all teams, allowing them to prepare for potential risks and become more agile in the face of setbacks.

Resilient Brand Reputation

Underlying all of the internal benefits of supply chain visibility is the effect the consistent and analytical use of supply chain data has on branding. Several benefits serve the brand as a whole:

- Customer service capabilities improve with traceability and data records

- Response times to risks, customer needs and market changes improve as trends become visible

- Supplier collaboration improves, building long-term partnerships that increase positive word of mouth marketing in the industry

- The company can better set customer expectations, resulting in better reviews and net promoter scores

- Environmental safety and responsibility is tracked and optimized, which improves the lives of consumers and employees alike

What Is Poor Supply Chain Visibility?

Poor supply chain visibility happens when data is lost, missing or siloed within departments or partner companies. Poor visibility results in delayed reactions to changing markets or environments, unreliable data, lack of traceability and blind spots. These problems slow down production, reduce revenue numbers and erode the trust of internal and external stakeholders.

Supply chain visibility initiatives fail for many reasons, but mostly because of a lack of complete commitment that comes from the top down and across all links in the supply chain. This highly collaborative initiative thrives in an environment of planning and follow-through. If these four areas don’t receive the attention they deserve, consider the strategy at risk of failure.

Lack of Business-Level Goals

All the important strategy planning methods and checklists apply when setting up a visibility initiative. To avoid this pitfall, pay careful attention to setting up:

- SMART goals that tie back to business objectives

- Strategy objectives upstream of technology, people and process objectives

- Change management

- Stakeholders and stakeholder management

- Initial project (MVP) goals and objectives

- Regular check-ins and meetings to track progress and iterate where necessary

Understand what business objective you seek to improve and work backward from there. The business objective will define what technology, partners and data you use throughout the project.

Most importantly, publish these goals, make them visible to the entire company, discuss the impact of the supply chain visibility and enforce the initiatives with departments and individuals.

Inconsistent Implementation

Partial implementation will wreck an otherwise well-thought out strategy. Implementation not only means technological (choosing, purchasing and installing the right software), but also communicating with stakeholders within the company and partner companies.

A solid change management plan and contingencies for uncooperative stakeholders or siloed data will come in handy.

Inaccessible Data

Siloed, inaccessible, unusable or unknown data and data sources will complicate or kill the supply chain visibility strategy.

Avoid this by taking inventory of technology used by all stakeholders and pay special attention to planning how data will be combined, cleansed and transformed. Use supply chain master data management principles and tools to build the data structures for the most impactful data you own, and save mutable data for later projects.

Failure to Iterate

Build, test, analyze, iterate, repeat. Companies that launch a supply chain visibility strategy without understanding what they hope to improve, how they will measure those improvements and what they want to do after they see improvements will waste time and money.

When you plan to analyze and optimize from the beginning, the pressure to make the project perfect from the beginning decreases, which helps reduce scope creep and improve communication. Once you’ve identified the problem areas for your supply chain visibility, you can start working on improving them.

5 Steps on How to Increase Supply Chain Visibility

The best way to increase your supply chain visibility is to make this a company-wide objective that requires cooperation from all parts of the business. Follow these five steps:

- Plan: Goals, objectives, metrics and intended outcomes for each stakeholder and the visibility of data across the organization.

- Wrangle your data: Understand your data landscape across all suppliers and stakeholders, map the most valuable metrics for each in relation to business objectives and plan how all that data will transfer and transform into usable forms.

- Communicate: Communicate with internal and external stakeholders at all major points in the visibility project. Build buy-in by discussing benefits and take reservations seriously.

- Implement technology: Only after planning and communicating should you purchase and spin up new technology for the supply chain, as capabilities and needs differ widely across options for integrations, analytics, data cleansing, communication and more.

- Assess and iterate: Seek to understand not only the progress of the visibility project, but why it has unfolded in that way and how to improve outcomes in the next steps.

Examples of Supply Chain Visibility

Companies need to build the technology stack that meets their unique industry and partner needs, but these are some common supply chain visibility technology types that speed implementation:

- Enterprise resource planning (ERP) software houses supply chain, financial, customer and vendor data all in a central location. When connected with outside tools, an ERP’s data is invaluable.

- Supply chain management (SCM) software works similar to an ERP but focuses primarily on the materials, manufacturing and logistics of the business. It doesn’t typically include much in the way of customer or employee data.

- MDM software helps companies build a usable foundation of master data that underpins all other data.

- Data analytics software gives teams an interface for data exploration and analysis. These may be included in some ERP or SCM software options.

- IoT devices and sensors paired with cloud-connected data systems track shipments of materials and products throughout the supply chain, sending data back to the company’s analysis tools.

What Are the Differences Between Supply Chain Visibility and Supply Chain Transparency?

Transparency is needed for visibility, and both states contribute to an optimized and agile supply chain. While the terms are similar, they differ in scope: visibility describes the entirety of the supply chain, while transparency happens between two partners.

| Term | Definition |

|---|---|

| Supply Chain Visibility | Describes the entirety of the supply chain; happens when the company can ingest data from partners, analyze it and use those insights to improve business outcomes. |

| Supply Chain Transparency | Describes a relationship between two partners; happens when vendors, suppliers and stakeholders share critical data with the organization and vice versa. |

Supply chain visibility happens when the company can ingest information from all their partners, analyze those data points and react to them in ways that improve business outcomes.

Supply chain transparency happens when vendors, suppliers and stakeholders share critical data with the organization and vice versa. While companies may choose to hold back some of their proprietary data, the more they can share about the processes that impact manufacturing or shipments, the better.

Supply Chain Visibility Trends in 2025

Supply chain visibility keeps improving with new advances in technology. A few trends stand out that increase the security, speed and accuracy of supply chains. Those are:

- Blockchain: The technology that cryptocurrency and NFTs run on provides a secure record, meaning it’s immune to tampering and can track materials and shipments across the supply chain. This is vital to ESG, sustainability and carbon emissions tracking efforts and to reduce counterfeit products.

- AI and ML: Supply chain technology has begun implementing AI and ML to increase automation, identify anomalies and problems earlier and provide solutions to complex problems. AI and ML can quickly produce answers to complex questions based on terabytes of data, which speeds up decision making.

- Advanced analytics tools: Today’s advanced analytics have moved beyond visual reporting to providing context and analysis to data, including forecasting. These tools rely on real-time data to recalculate predictions, allowing for quicker pivots in rapidly changing market environments.

What Should You Look for in Supply Chain Visibility Tools?

A good supply chain visibility tool will do the job of pulling together data from across the supply chain and making it accessible and usable by business units and partners. Beyond that, you should look for features that meet your company’s goals. When planning and looking for supply chain visibility tools, consider whether you need features that provide:

- Risk management

- Manufacturing data management

- Automation

- Regulatory compliance

- Audit capabilities

It’s crucial to understand what you need from your visibility initiative and how it will serve your business objectives before purchasing.

Increase Supply Chain Visibility with Profisee

Profisee makes it easy to integrate data about your supply chain from a variety of different sources, providing a powerful platform to standardize, deduplicate and enrich your data for reporting, AI, supply chain optimization and other initiatives.

Tamara Scott

Tamara Scott is a writer, editor and content strategist with over a decade of experience located in Nashville, TN. Tamara holds a Master's in English from Belmont University, formerly served as Director of Content for TechRepublic, and her work has appeared in ServerWatch and EPI-USE.com, among others. When she's not crafting SEO-informed and conversion-ready content for SaaS and IT service companies, she's probably at home on her pottery wheel. Connect with her on LinkedIn.