- Oil & Gas Use Case

Asset Optimization During Exploration & Drilling

How Profisee can help oil & gas companies maximize efficiency and minimize downtime by integrating and managing asset data.

Oil & gas companies can achieve higher operational efficiency, cost savings and safety by optimizing asset management during exploration and drilling. An MDM solution ensures a single, trusted view of asset deployment & details across multiple systems, enabling proactive asset placement, better utilization of existing assets and improved environmental compliance reporting.

Data Domains

Asset, Location, Chart of Accounts

Business Problem

Maintenance Inefficiencies, Compliance Challenges

Teams Impacted

Operations, Maintenance, Health & Safety, Compliance

MDM Impact

MDM ensures a single source of truth for asset data

Asset life-cycle data is siloed & inconsistent

- Inefficient Maintenance & Scheduling: Lack of reliable data leads to reactive rather than preventive maintenance, increasing downtime.

- Fragmented Asset Visibility: Asset data resides in silos across various systems or subsidiaries, making it challenging to track utilization & placement and optimize utilization of existing assets.

- Unplanned Downtime Costs: Operational interruptions due to equipment failure or unavailability of required assets are costly and largely avoidable with proactive data management.

- Regulatory Compliance Challenges: Meeting stringent environmental and safety regulations is hindered by inconsistent and incomplete data.

- Underutilized Resources: Poor insight into equipment availability and capacity reduces operational efficiency.

Ensuring a single source of truth for assets

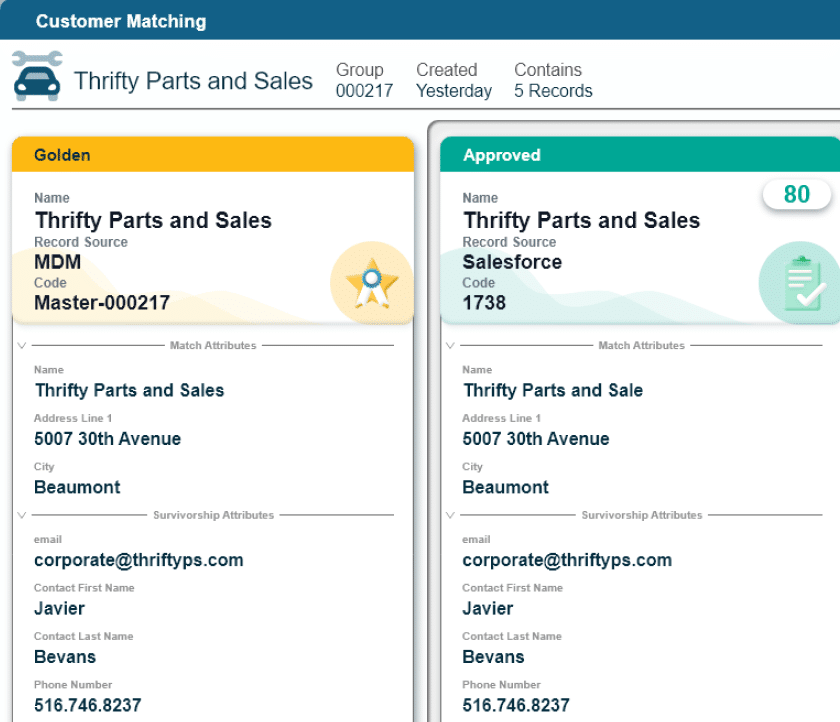

- Data Consolidation & Cleansing: MDM consolidates asset data from multiple sources, ensuring accuracy, standardization and alignment across systems.

- IoT Integration: Real-time IoT data can be matched to the accurate asset to more effectively track performance, predict failures and schedule maintenance optimally.

- Data Quality Monitoring: Continuous monitoring ensures the validity and timeliness of asset data, reducing errors and inconsistencies.

- Predictive Analytics: Continuous monitoring ensures the validity and timeliness of asset data, reducing errors and inconsistencies.

Streamlined operations and reduced downtime

- Reduced Downtime: Proactive and predictive maintenance reduces the likelihood and duration of unplanned outages.

- Optimized Resource Utilization: Assets are effectively tracked, utilized, and scheduled, improving operational efficiency.

- Compliance Excellence: Reliable data ensures adherence to environmental and safety regulations.

- Cost Savings: Preventive maintenance and optimal resource usage lower operational expenses.

- Enhanved Safety: Data-driven insights improve workplace safety and reduce risks.