Table of Contents

- What Is Supplier Information Management (SIM)?

- What Are the Benefits of Supplier Information Management (SIM)?

- What Do Supplier Information Management Systems (SIM) Do?

- Supplier Information Management Best Practices

- How to Implement Supplier Information Management (SIM)

- Working Smarter with SIM

- Frequently Asked Questions

Key Takeaways

Supplier information management (SIM) centralizes and standardizes supplier data to support compliance, efficiency and smarter decision making.

Implementing SIM requires the right mix of technology, process and governance — with tools like Profisee to enable automation, data quality and system integration.

In analytical use cases, golden records improve reporting accuracy and enable flexible, powerful analysis by serving as a single source of truth.

The spread of globalization spun intricate webs of supply chains that businesses around the world depend on to bring their products to market. Business success is now closely tied to effective supplier relationship management — something that presents numerous challenges to data practitioners.

Without a reliable system for tracking supplier data, companies risk delays, compliance issues and operational inefficiencies. This is where supplier information management (SIM) comes in. This guide will walk you through what SIM is, how it works, why it matters and how to put it into practice.

The State of Master Data Management (MDM) 2026

What Is Supplier Information Management (SIM)?

Supplier information management (SIM) is the process of collecting, storing, maintaining and using data about suppliers to support business operations. SIM provides a centralized approach to managing everything from contact details and banking information to certifications, compliance documents and performance metrics.

SIM ensures that your organization always has accurate, up-to-date and trusted supplier information available to support procurement, risk management and supplier collaboration efforts. This can be accomplished by using dedicated supplier information management software tools like HICX and Graphite Connect or through a master data management (MDM) tool like Profisee.

What Are the Benefits of Supplier Information Management (SIM)?

We’ve already touched on a few ways in which SIM can deliver operational and strategic value — including improved data accuracy and consistency, better compliance and risk management and increased efficiency — but supplier information management also helps in at least two other ways: better vendor onboarding and optimized supplier spending.

Vendor Onboarding

Vendor onboarding can be a tedious and time-consuming process. Depending on the size and nature of your business, onboarding new vendors might require a fair amount of due diligence — ensuring vendors follow certain security protocols, maintain compliance with relevant regulations and are insured, to list a few examples.

SIM can help here by standardizing the onboarding process and automating some of the processes that would otherwise have to be done manually. This not only helps avoid redundant processes that can lead to onboarding delays but also reduces the risk of human error that can lead to even bigger problems like security breaches and noncompliance events.

Supplier Spending

Enterprise-sized organizations might maintain relationships with hundreds or even thousands of suppliers, making it challenging to keep trustworthy data about all of them in a central location. This leads to various inefficiencies when it comes to procurement management, as some business units might use the same supplier for certain materials without knowing it.

By unifying supplier data from across the enterprise and identifying matching records, businesses can negotiate better deals on procurement and consolidate accounts. This also presents an opportunity to uncover which suppliers perform the best and offer the best prices in cases where different business units use different suppliers for the same materials.

What Do Supplier Information Management Systems (SIM) Do?

Supplier information management systems are software tools designed to support SIM processes. They typically offer the following capabilities:

- Data Centralization: Create a single source of truth for all supplier data across regions and departments.

- Onboarding Workflows: Automate the process of collecting required documents and approvals from new suppliers.

- Data Validation and Cleansing: Ensure data is accurate, complete and standardized.

- Governance and Compliance Tracking: Monitor certificates, licenses, insurance and other compliance documents.

- Performance Monitoring: Track KPIs like delivery times, quality metrics or dispute history.

- Integration with ERP and Procurement Systems: Ensure consistent data flows between SIM and your broader technology stack.

SIM tools are also sometimes called supplier relationship management (SRM) systems. Products can range from supplier onboarding tools to suite-style solutions that handle a wide variety of different supply chain functions, but some popular tools include SAP Ariba, Graphite Connect, Coupa and apexanalytix.

Supplier Information Management Best Practices

To get the most out of your SIM efforts, it’s important to maintain good data management practices. As with many data initiatives, this starts with defining your data standards upfront — what does “good” look like when it comes to data quality? What data is required of suppliers, who owns it and how does it need to be used?

From there, you can map out the processes associated with onboarding new suppliers so you can start thinking about how you will automate as much of it as possible. Depending on the size and complexity of your organization, this could be as simple as building a form, but more likely than not, onboarding requires multiple touchpoints and documents from new vendors.

Using Profisee, you can create FastApps for data stewards to use when onboarding new suppliers and configure custom workflows to automate different steps of the process. Standalone SIM or SRM tools might have similar capabilities, but however you approach this step, be sure to take your data governance policies into account and build rules for data validation so that data is formatted correctly when stewards create new records.

If possible, incorporating a look-up-before-create feature is a good idea to prevent duplicate records from being created accidentally. Only authorized users should be able to create new records or update existing ones, and it’s a good idea to make sure that expectations surrounding the onboarding process are clearly communicated to vendors.

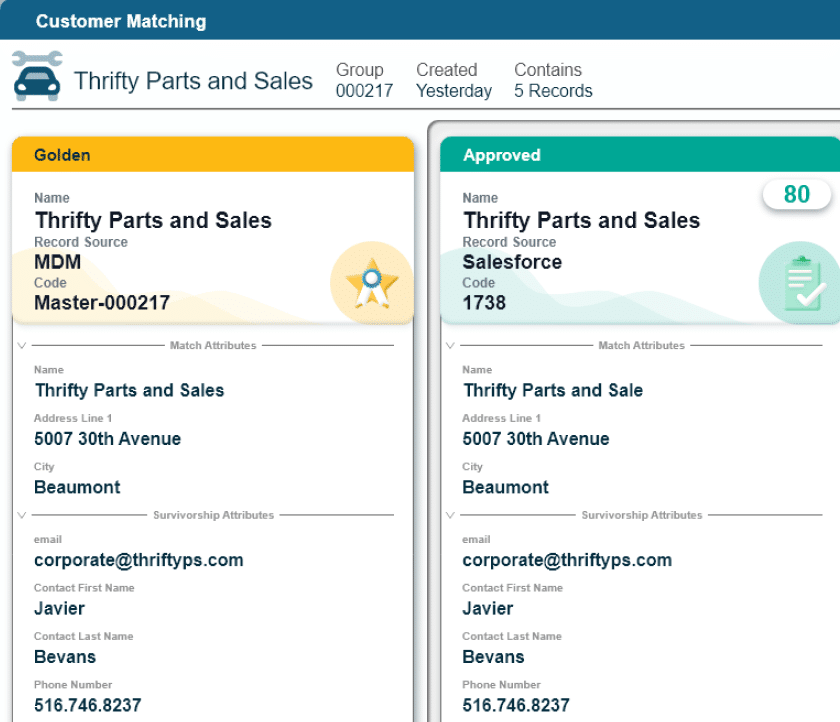

For existing records, this is a good opportunity to cleanse and deduplicate. There will inevitably be duplicate records after you’ve integrated data from across the enterprise, but tools with automated matching and merging capabilities like Profisee can help you ensure your data is accurate, unique and standardized. Monitor data quality over time to make sure data remains useable to the broader organization.

How to Implement Supplier Information Management (SIM)

Implementing SIM requires a strategic approach that balances technology, process and people.

Technology

Start by assessing the current state of your supplier data. Identify where supplier data is stored and any associated pain points and then implement a SIM solution that addresses those pain points. Again, this could be a standalone SIM/SRM tool or an MDM tool like Profisee. No matter which path you take, look for tools that can integrate with your ERP(s) and that support your workflow needs for automating tasks like onboarding.

Process

With a tool selected, you can integrate data from across the organization and cleanse it. Profisee features built-in integration capabilities as well as automated matching and merging with configurable survivorship rules. Once records have been deduplicated and standardized according to data governance policies, you can further enrich them and make them available to the teams and downstream systems that need access to them.

People

You will of course want to train your team on how to work with the new tool, but before you do that, it’s important to define roles and responsibilities and decide who owns what data across the organization. Security and compliance should be chief concerns here. Make sure people who don’t need access to the data can’t do so, but just as importantly, ensure that people with access have the appropriate level of access.

Regularly monitor data quality, supplier engagement and system usage to refine your approach and make improvements. Supplier information management is an iterative process; it doesn’t end once you implement a software tool.

Working Smarter with SIM

Supplier information management is no longer a nice-to-have — it’s a business imperative for organizations looking to streamline operations, ensure compliance and make smarter procurement decisions. By combining the right technology with strong processes and governance, companies can unlock the full value of their supplier data and build more resilient, efficient supply chains. If you’re ready to take the next step, Profisee offers the tools and expertise to help you do just that.

Master Supplier Information Management with Profisee

Frequently Asked Questions

What is vendor information management?

Vendor information management is another term for supplier information management. Both refer to the process of collecting and maintaining accurate data about the vendors or suppliers a company does business with. The term “vendor” is often used interchangeably with “supplier” depending on the industry or organization.

What is supplier/vendor information?

Supplier or vendor information includes any data related to a company’s external suppliers. This may include contact details, tax ID numbers, payment terms, compliance documents, performance metrics and product or service offerings. Managing this information accurately is critical to maintaining smooth operations and meeting regulatory requirements.

What is an example of supplier data?

A typical example of supplier data would be the full profile for a supplier, including their legal name, contact information, W-9 form, ISO certification, primary contact, payment terms, bank account details and a record of on-time deliveries. This type of information is often stored in a centralized SIM platform and kept up to date through automated workflows and supplier self-service portals, though it can also be done with an MDM tool like Profisee.

Forrest Brown

Forrest Brown is the Content Marketing Manager at Profisee and has been writing about B2B tech for eight years, spanning software categories like project management, enterprise resource planning (ERP) and now master data management (MDM). When he's not at work, Forrest enjoys playing music, writing and exploring the Atlanta food scene.