Hello, I’m Christopher Dwight, VP of MDM Initiatives at Profisee. Today, I want to explore a significant challenge that many manufacturers face: managing indirect maintenance, repair, and operations (MRO) spend. This is a common issue we’ve encountered with several customers, and I’d like to share how Profisee Master Data Management (MDM) can help mitigate this problem effectively.

A Common Manufacturing Scenario

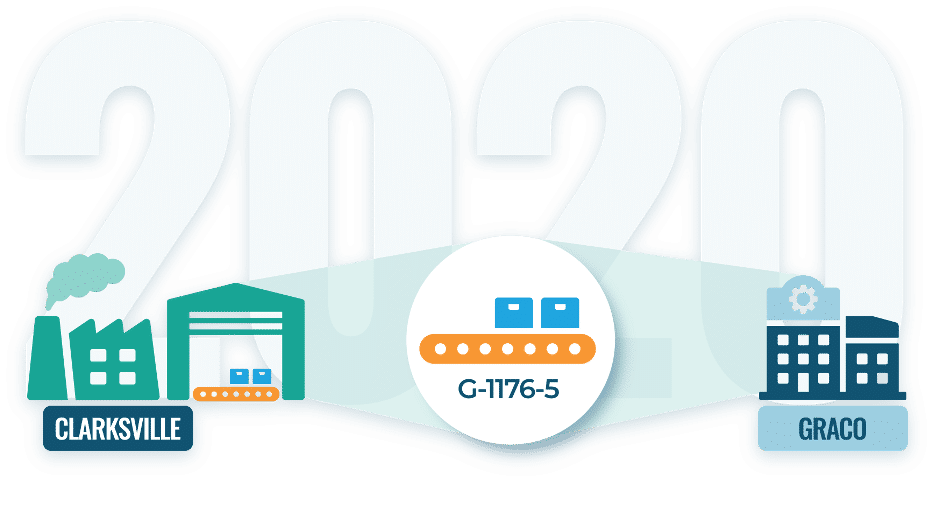

Consider a global manufacturer operating multiple plants and facilities. For example, our customer has plants in Clarksville and Sunderland. In 2020, the Clarksville plant acquired a spare conveyor belt from a company called Graco, with the part number G-1176-5. This spare part has been in the Clarksville warehouse, available for use in case of need.

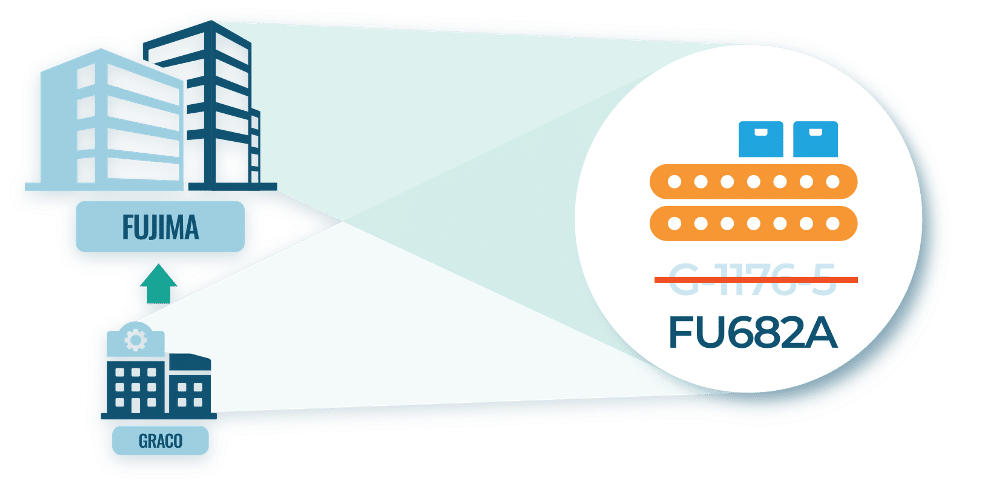

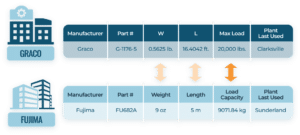

Fast forward to 2024, and the Sunderland plant needs to acquire two identical conveyor belts. However, during the intervening years, Graco was acquired by another company called Fujima, which renumbered their parts to align with Fujima’s standards. Consequently, the conveyor belt previously known as G-1176-5 is now listed as FU682A.

The Ripple Effect of Inconsistent Data

Such changes happen frequently in large, global manufacturing firms. While this seems like a simple change, it can lead to significant cost overruns and operational inefficiencies. Let’s delve into how this data inconsistency can cause a ripple effect.

When Clarksville purchased the Graco part G-1176-5, it was entered into multiple systems, including:

- MRO tools

- Inventory or stock management tools

- Corporate procurement software or enterprise ERP systems

Years later, Clarksville experiences an unexpected breakdown and needs two of these conveyor belts. They only have one in stock, halting production. Under pressure, the plant managers call centralized procurement to rush order another belt. Despite diligent efforts, the procurement team, unaware of the part number change, places an expensive rush order with Fujima.

Unbeknownst to them, the Sunderland plant already has two of these belts in inventory under the new part number FU682A. This oversight leads to wasted time, delayed production, and unnecessary capital expenditure.

The Profisee Solution

So, how can we solve this problem and reduce unnecessary MRO costs at scale? Profisee’s Adaptive Master Data Management Platform offers a robust solution.

Standardize Attribution and Description Information:

Profisee can standardize the attributes and descriptions of parts, beyond just the manufacturer’s part number. For example, a part’s attributes might change from imperial to metric units when the manufacturer changes, leading to inconsistencies.

Intelligent Fuzzy Matching:

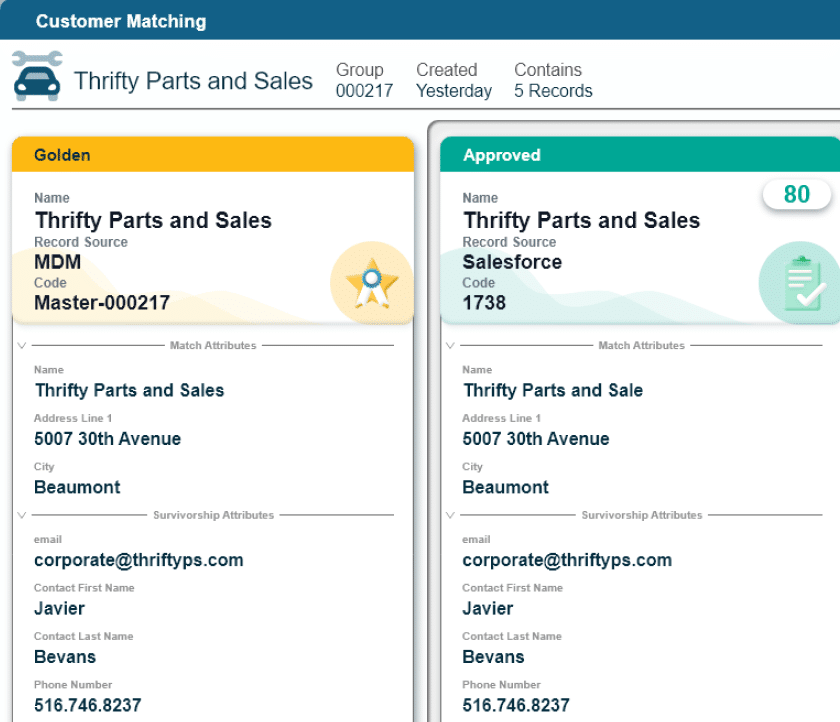

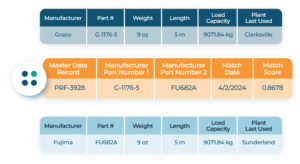

Profisee employs intelligent fuzzy matching across attributes to determine that parts like FU682A and G-1176-5 are identical. By creating a comprehensive golden record, the procurement team can confidently identify these parts, regardless of the part number changes.

Automation and Notifications:

Profisee automates complex business processes and sends notifications when part numbers are combined. This ensures that all stakeholders are informed, streamlining approvals and changes to master data records.

Seamless System Updates:

With an operational MDM deployment, Profisee can automatically update procurement systems, MRO systems, and other downstream systems. This ensures that all stakeholders, from plant managers to procurement teams, are using consistent and trusted data.

Real Financial Benefits

By addressing data inconsistencies at scale, manufacturers can significantly reduce unnecessary spend, streamline procurement processes, and improve organizational collaboration. High-quality, trusted data powered by Profisee’s MDM can transform MRO operations, yielding substantial financial and operational benefits.

Thank you for taking the time to understand how Profisee Master Data Management can help manage and reduce indirect MRO spend.

For this reason, it is important to be judicial and selective when deciding to take on incremental use cases to an existing MDM implementation. Read our complete guide to Selling MDM to Leadership for tips, best practices and insights that I’ve seen work for MDM practitioners working to expand their MDM program into multiple business-centric use cases.

Selling MDM to Leadership

Christopher Dwight

Christopher is a well-respected master data management (MDM) thought leader and the VP of MDM Strategic Programs at Profisee. Christopher has been in the enterprise information management and MDM space for more than 25 years, including senior leadership stints at Oracle and Informatica. Over those years, Christopher has engaged with hundreds of organizations to assist them in their data management strategies and MDM journeys.